Materialise Production Planning & Scheduling

Maximize production capacity and throughput for smarter resource usage

Achieving the most efficient use of your materials and machines is crucial when you’re manufacturing components at scale using 3D printing. The Materialise Production Planning & Scheduling module helps you boost productivity by nesting parts and offers powerful visual tools for scheduling and tracking work orders throughout the production process.

Benefits

Maximize capacity

Speed up production time and optimize material and machine usage by efficiently nesting multiple geometries from work orders.

Configure priority scheduling

Schedule jobs based on the most relevant priorities, such as due date, minimization of material switchover, or production parameters.

Improve planning and coordination

Use powerful Gantt charts to build a visual overview of every work order across your entire production floor and track progress to deliver on time.

Features

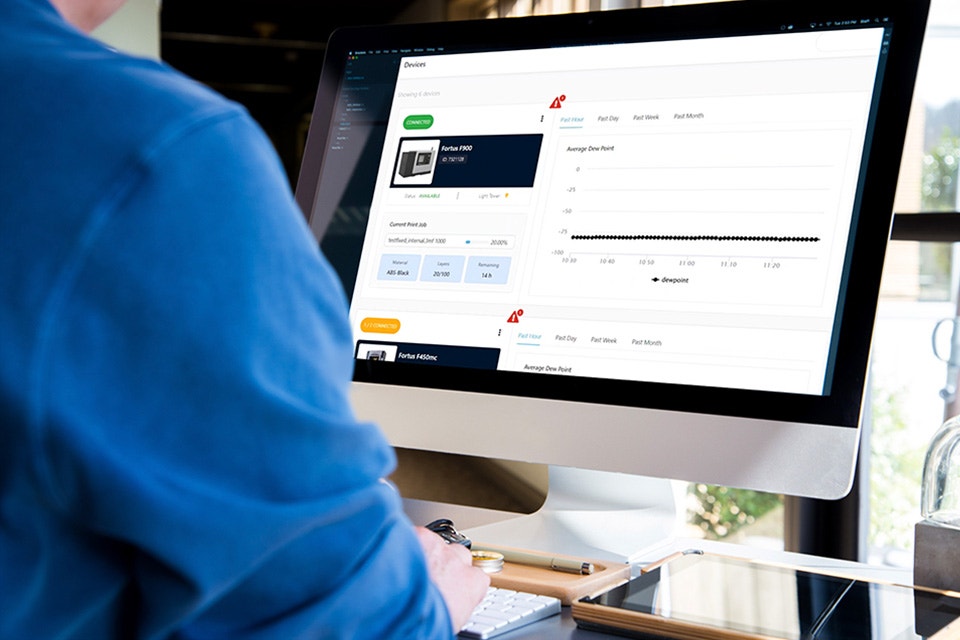

End-to-end traceability

Capture and store data throughout the 3D printing lifecycle for quality review and easy reordering.

Track job failures and downtime

Use checklists attached to manufacturing travelers to record reasons for job failures and machine downtime.

Data analytics and reporting

Detect production bottlenecks, track resource usage, and analyze ROI across your operations.

You might also like

Track non-conformances and CAPA reports to drive continuous improvement and meet regulatory compliance.

Plan and manage the entire AM process to maximize throughput, optimize capacity, and gain complete visibility across your operations.

Leverage business intelligence to gain insights, drive demand, optimize costs, and enable sustainable growth plans while de-risking AM deployment.