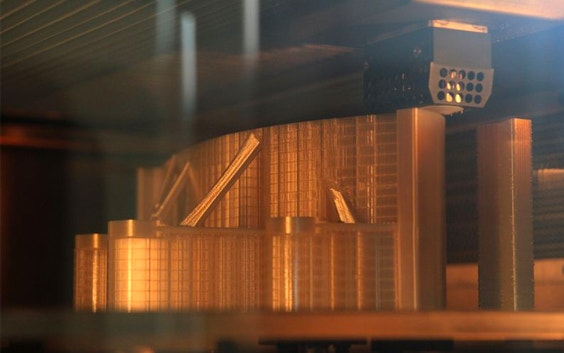

Material

Ultem 9085

Ultem 9085 is a pioneering flame-retardant thermoplastic that is strong, and lightweight. With its superior mechanical performance, high strength-to-weight ratio, and high thermal and chemical resistance, this material is suitable for highly functional prototypes and production-grade end-use parts, particularly in the aerospace and automotive industries.

Technical specifications

| Maximum part dimensions | 914 x 610 x 914 mm 406 x 355 x 406 mm (online orders) |

| Standard accuracy | ±0.15% (with a lower limit on ±0.2 mm) |

| Layer thickness | 0.25 – 0.33 mm |

| Minimum wall thickness | 1.2 mm |

| Minimum detail size | 0.3 mm |

| Interlocking or moving parts | No |

| Internal channels | No |

| Surface structure | Rough surface with visible layers |

Datasheet

| PARAMETER | VALUE | UNIT | METHOD |

| ASTM D792 | 1.34 | g/cm³ | |

| ASTM D638 | 70 | MPa | |

| ASTM D638 | 2,465 | MPa | |

| ASTM D790 | 100 | MPa | |

| ASTM D790 | 2,400 | MPa | |

| ASTM D256 (Notched,Izod) | 88 | J/m | |

| ASTM D638 | 5.4 | % | |

| ASTM D648 (@1.82 MPa) | 173 | °C | |

| DSC (SSYS) | 186 | °C |

Actual values may vary with build conditions and in relation to the part’s geometry and orientation.

Please get in touch with our team for more information and guidance.

Finishing degrees

The right finish can transform your print into a product. Explore the post-production finishes we offer for this material. If you have any questions or special requests, get in touch with us.

Train and learn

Get more from your next project with helpful resources dedicated to Ultem 9085 and fused deposition modeling.