CASE STUDY

94% Lighter, 50% Cheaper, and More Performant: Optimizing the Design of a Metal Suction Gripper

Production tools are one of the applications where additive manufacturing (AM) truly shines. One illustrative example of this is the redesign of a suction gripper that lifts light, cylindrical objects in a series production system. The redesign, in which Materialise worked closely with the customer, resulted in several significant improvements. To name but one: manufacturing costs per gripper were halved.

The challenge

Reduce manufacturing cost per part

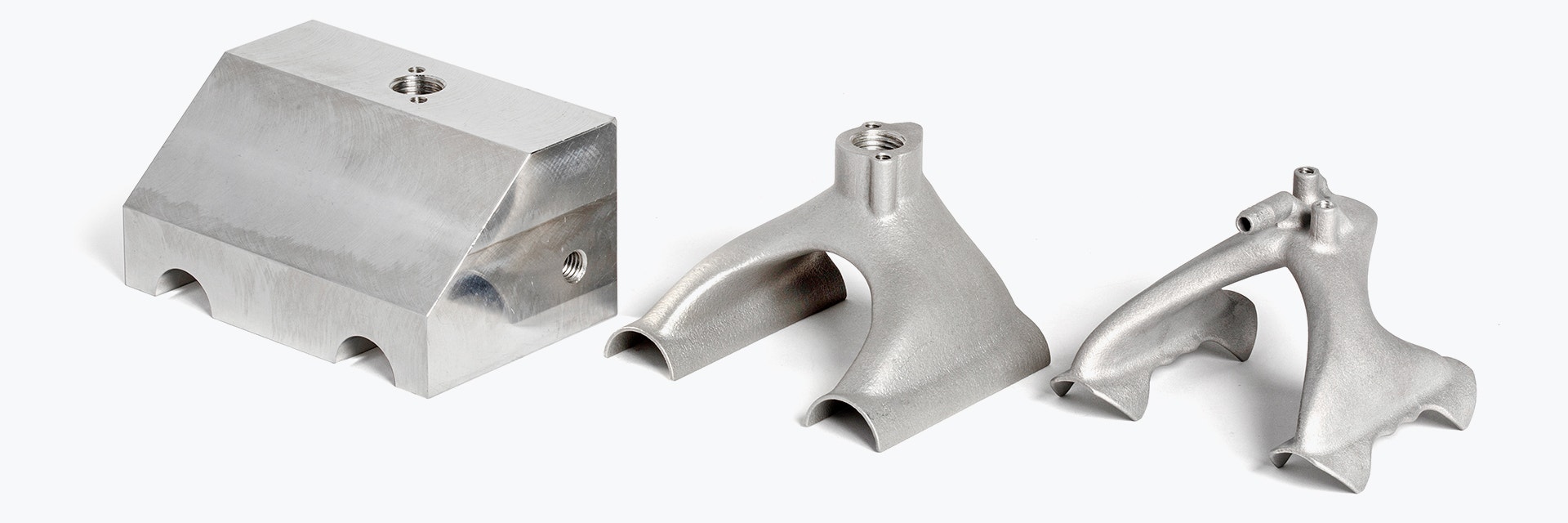

In this case, our customer’s suction gripper was originally designed so that it could be manufactured entirely with conventional production tools. For the necessary internal channels, several straight holes were drilled from different directions in order to intersect each other. Openings were sealed with dummy plugs. To avoid increasing component costs further, the customer did not carry out any further milling work to reduce the volume of the gripper when possible.

The customer already had experience with additive manufacturing of plastic parts and was familiar with their advantages in terms of costs and efficiency, especially for production tools. Nevertheless, as with all redesign ideas, they had to start by asking themselves whether 3D printing would really be worthwhile in regard to this gripper as well.

The solution

Apply design for AM principles

Comparing their requirements for the gripper with 3D printing’s possibilities led to clear opportunities: lower manufacturing costs, lower weight to perform faster movements, shorter gripping cycles, better vacuum distribution, and fewer leaks.

The customer’s choice of material was aluminum. On the one hand, the metal is significantly more wear-resistant than plastic, yet still lightweight. On the other, it facilitates smooth surfaces that are easy to clean during ongoing production. Furthermore, aluminum is economically well suited for small- to medium-sized components with high value and small quantities.

After the customer had developed a 3D printing design themselves, they contacted Materialise to have the component produced in our facilities, and our Design and Engineering team quickly recognized that the design could be improved even further. Although the customer’s own design already offered a significant weight reduction, the production costs were higher than with the original production method and the internal channels were not aerodynamically optimized.

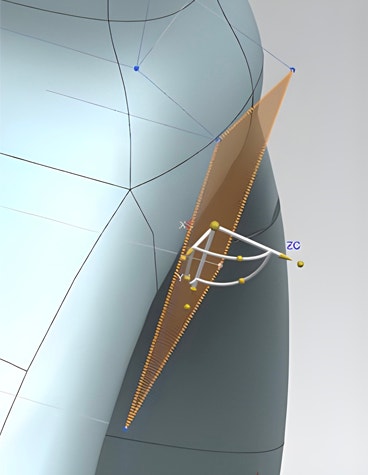

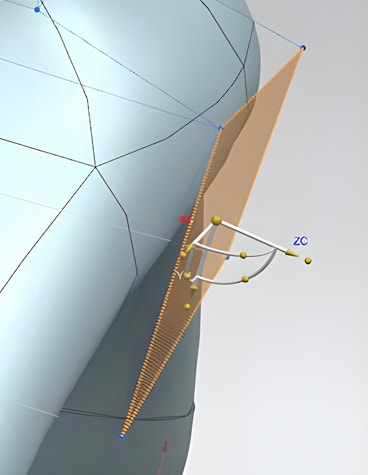

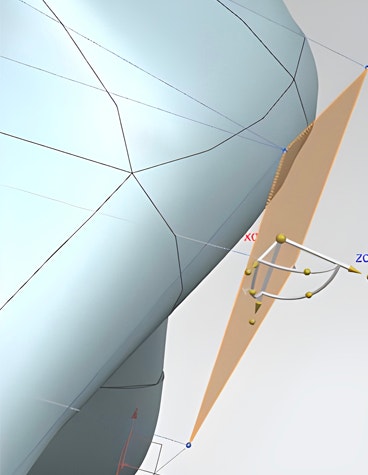

Our team used Siemens NX Realize Shape module to optimize the part’s design.

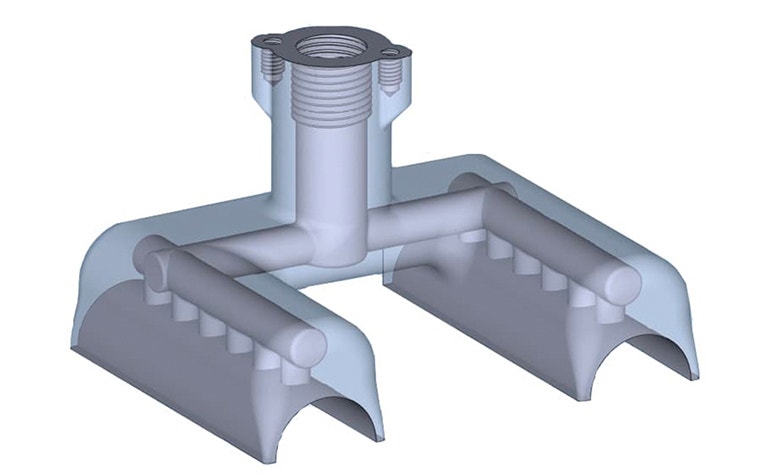

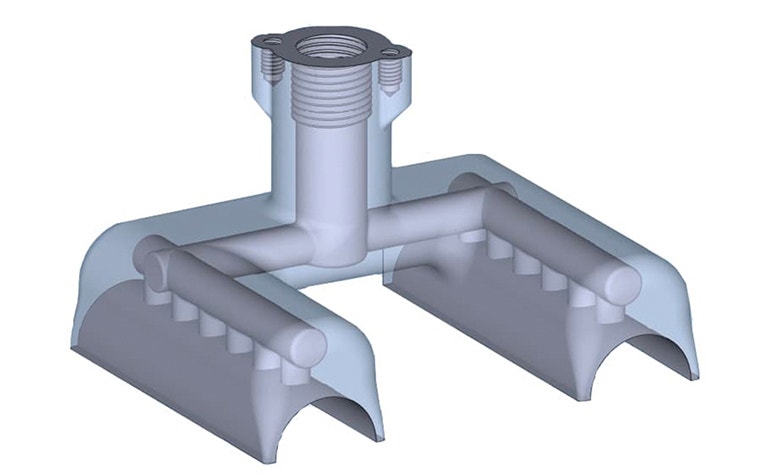

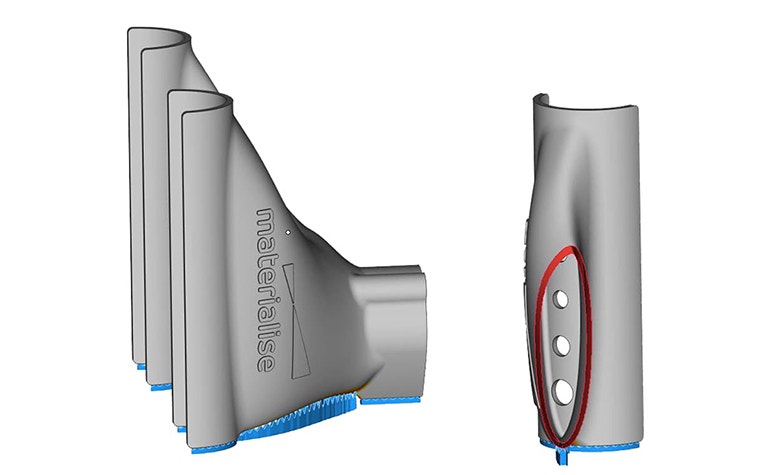

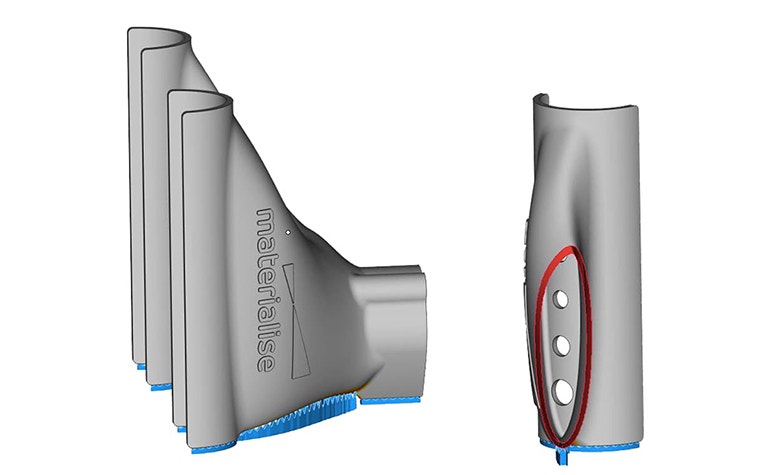

Having gotten the green light from the customer, our engineers got to work on further optimizing the 3D printing design. They used the Siemens NX Realize Shape module for the redesign, which enables free-form modeling. Using Materialise Magics software, the experts also optimized the geometry concerning the printing process. To achieve this, they used a preview function that can display all necessary support areas for a component in the selected component orientation.

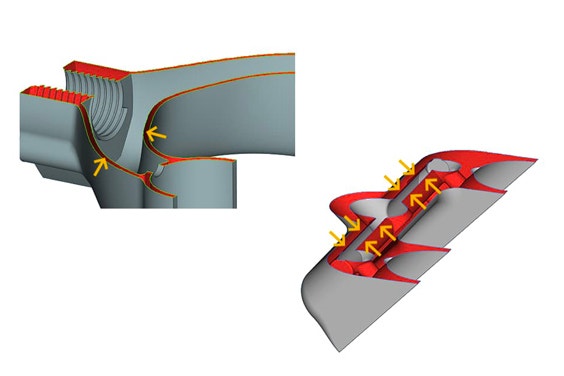

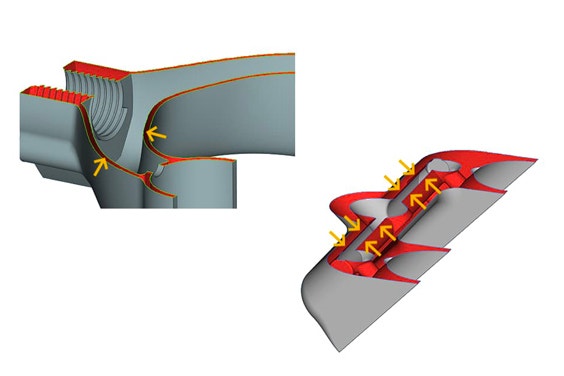

This enabled them to ensure that no support structures were needed inside the component to print the converging walls. The design team arranged the parts in the installation space in such a way that further minimized the number of required support structures and optimized the quality of the contact surfaces in the gripping area. It was also essential that the new design ensured homogeneous distribution of the vacuum on the gripping points. This makes picking up the cylindrical body more reliable.

Then, the Materialise engineering team reduced the tension lines by making the transitions between material thickness more fluid. This was important because stress lines not only negatively affect the external appearance, but also the mechanical properties of the final part.

The result

Reduced gripper volume

In this way, the total volume and weight of the component were reduced to a necessary minimum. This has a direct impact on material costs since unused material can be largely recovered and directly reused in metal 3D printing — unlike in metal cutting processes. Thus, significant costs are only incurred for the material that is actually required for the component and support structures. The small number of supports and minimal contact surface in non-critical areas with the component also has a positive effect on post-processing. This allows the support structures to be removed without heavy outlay in time and effort. As a final step, only the threads for the assembly had to be cut.

Compared to the customer’s original 3D-printed model, an additional time and cost advantage were achieved: the number of components in each build increased from 28 to 46. The new geometry of the component allows a significantly more efficient arrangement on the build platform, which also has a positive effect on the price per part.

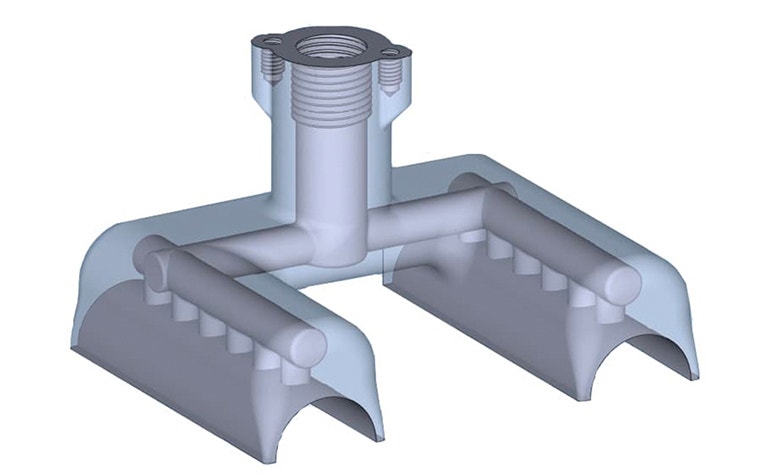

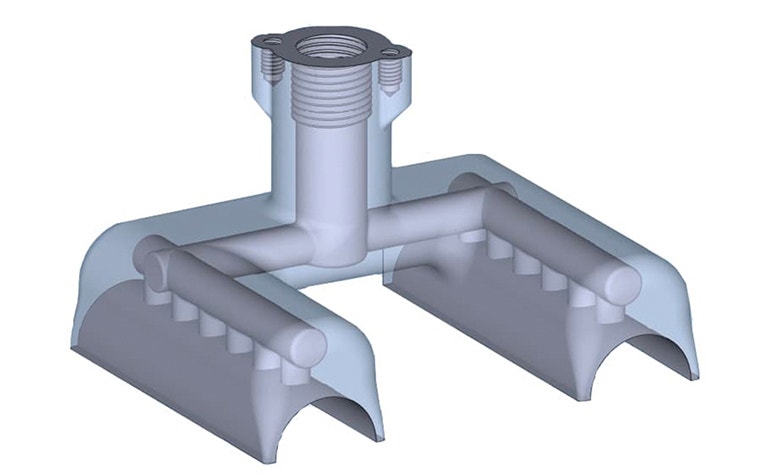

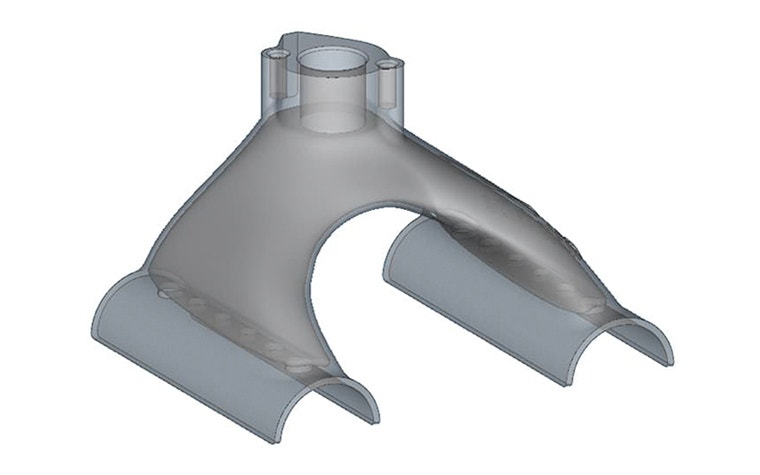

The final suction gripper design and the gripper’s suction areas.

A comparison of the volume values and manufacturing costs between the original tool, the first 3D-printed model, and the final design shows how much progress has been made: while the customer’s first designed-for-AM model already had 79% less volume than the original part. The cost per part has been reduced from €300 for the traditional tool to €150 for the Materialise version. The customer’s first 3D print design would have been 6% more expensive to produce.

Conventional design

Design:

- 242.900mm³

- 100%

Price:

- 300€

- 100%

3D printing design by the customer

Design:

- 50.590mm³

- -79%

Price:

- 317€

- +6%

Final 3D printing design by Materialise

Design:

- 15.150mm³

- -94%

Price:

- 150€

- -50%

All in all, the example of the suction gripper shows how additive manufacturing and an optimized additive design can be used to achieve a cheaper, lighter, and functionally optimized production tool. The example also demonstrates the decisive influence the quality of the redesign can have on the profitability of a project. In view of these massive improvements, the customer decided to have their suction grippers manufactured in the optimized 3D printing design in the future.

Share on:

This case study in a few words

Machinery and equipment

Design for additive manufacturing

Aluminum

Cost reduction

Weight reduction