CASE STUDY

How Fiberneering Reduced Their Data and Build Preparation Time by 90%

Fiberneering is a Dutch 3D printing factory that specializes in 3D printing large parts via a process similar to stereolithography (SLA) and digital light processing (DLP). When it comes to printing such large structures, they cannot be built as solid pieces. To do so would require too much material to be economically viable. Not only would it be too expensive, but the excessive amount of material would also create extra stress and lead to warping. Instead, Fiberneering must create interior structures to use less material while maintaining part strength.

These internal structures used to mean that they had to handle inconveniently large data files. The files held all of the necessary information but greatly slowed down every software operation during the process of preparing parts to be printed. Doing so for just one part took them almost 6.5 hours. They needed an improved workflow that could speed up their data and build preparation. Something with lighter files.

“With our previous workflow, print preparation took just as long as the printing process. We needed to find a new approach.”

— Jasper Bouwmeester, Owner and CEO, Fiberneering

Fiberneering was already at work with the Magics software, Materialise’s industry-leading data and build preparation software, to create drain holes and generate support. However, the internal structures were created in another software package, leading to very large data files. This was where Materialise’s Slice-Based Structures Module could help.

Slice-based technology is Materialise’s method of making large design files, often containing complex textures and internal lattices, more manageable — a feat that would greatly benefit the Fiberneering team. This procedure renders a representative model, but the actual file is not produced on the STL level. As such, the file remains light and easy to handle.

This means that the actions of saving, loading, positioning, editing, enhancing files, and generating support are all greatly accelerated — in fact, the Fiberneering team discovered that 90% less time was needed to do so with a test file.

“The Slice-Based Structures Module is simple to use, fast, and eases a lot of our previous frustrations,” says Jasper Bouwmeester, Owner and CEO of Fiberneering. “The team is no longer waiting around for slow processes to finish up. Now, we’re more productive than ever.”

99.4% less time spent on manual work

With the creation of each part, Fiberneering engineers must hollow their parts in order to save material and reduce printing time as well as create internal structures to maintain shape consistency and strength. Previously, this process took 20 minutes in CAD software. From there, it took 5 minutes just to transfer the design to Magics, and an additional 6 hours finalizing the data and build preparation.

“We’re a small team, so time is of the essence,” shares Jasper. “With our previous workflow, print preparation took just as long as the printing process. We needed to find a new approach.”

In a conversation with Materialise experts on how to improve the workflow, the software team had several suggestions right away that could ease these pain points. First, they consolidated their software to use only Materialise software for the data and build preparation. Hollowing and structure generation that was previously done using CAD software could instead be completed automatically via Magics, optimizing and streamlining the process, eliminating the need to switch between applications, reducing the time needed, and limiting errors.

Next, they implemented the slice-based operations to reduce file sizes and speed up processes. Many steps of data and build preparation can be automated, which is accelerated even more thanks to the smaller file size. This greatly reduced not only the overall preparation time by 90%, but also how much of that time must be spent doing manual tasks. Thanks to slice-based operations, the latter was cut by a whopping 99.4%.

Structure choice makes a huge difference

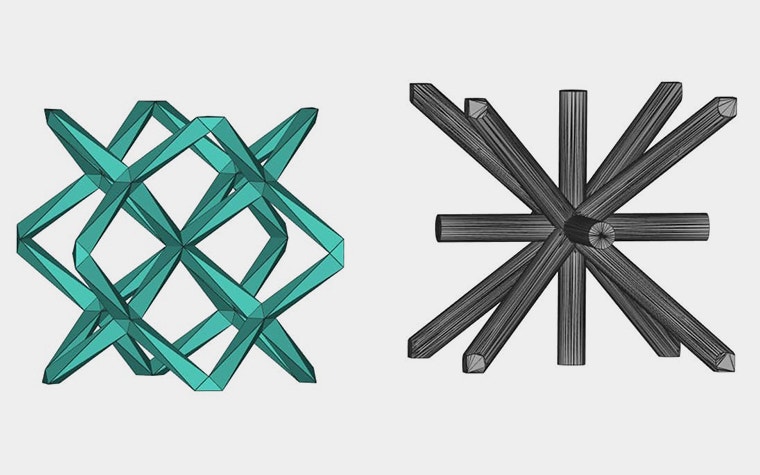

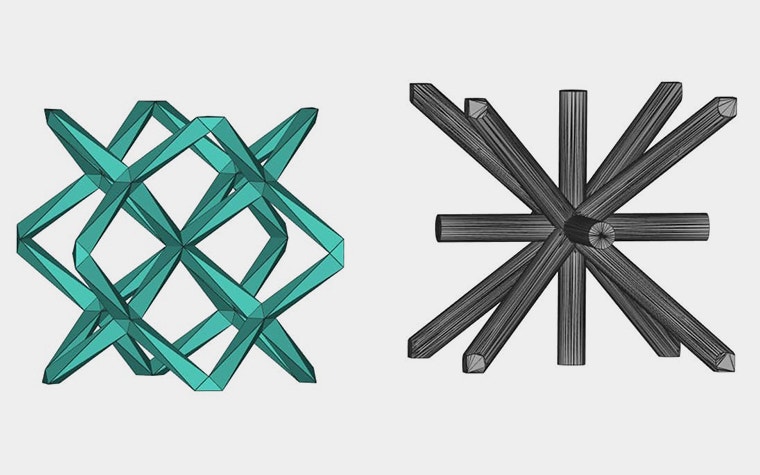

While working with the Fiberneering team on improving their workflow, Materialise Application Engineer Laurens Schulte noticed that it wasn’t just slice-based operations that would reduce the size of their files, but that changing their interior structure shape would as well.

“The lack of slice-based operations wasn’t Fiberneering’s only pain point when it came to their large file sizes. The interior structure shape they utilized was causing issues as well,” explains Laurens. “In this case, optimizing unit cells reduced the triangles per cell immensely, and the result was a lighter part that was just as strong and required less material and preparation time.”

After reviewing Fiberneering’s needs for internal structures, the team found Dode-Thin unit cells to be the best option, replacing Reinforced Body Centered Cubic (RBCC) cells. These Dode-Thin structures consisted of only 250 triangles per cell while the previous choice easily took up more than 5,000 triangles per unit cell. The new structures not only enabled smaller file sizes since they are created on the slice level, they even made it easier for their team to avoid shrinkage marks.

With the help of Materialise experts, Fiberneering was able to greatly reduce their time spent preparing files for printing. Thanks to the seamless integration of Materialise software, the entire workflow was improved, from data preparation to loading the design to the printer via the Standard DLP Build Processor. Now that their team is benefitting from this enhanced data and build preparation, they can shift their focus to other valuable tasks to further advance their organization.

“The team at Materialise is very friendly and open to working with us to find the solution to our specific challenges,” says Jasper. “The know-how is certainly there, and I was pleased to work with them to improve our workflow.”

Share on:

This case study in a few words

3D printing factories

- Materialise Magics

- Slice-Based Structures Module

- Standard DLP Build Processor

New approaches to customers’ existing production processes