Materialise Support Generation

Optimizing support structures is key to preventing deformation and ensuring a successful build. Too little support or incorrectly placed structures may cause the build to crash, but too much can lead to more waste. Semi-automate support structure generation to reduce data preparation time, minimize human error, and simplify post-processing.

Benefits

Semi-automated workflows

Follow suggested processes to quickly generate optimal support and avoid human errors.

Time savings

Gain efficiency during data preparation and post-processing thanks to automation and optimized support structures.

Better part quality

Boost the quality of your parts with easily removable support and a lower risk of build failures.

Ideal for the 3D printing technology you use

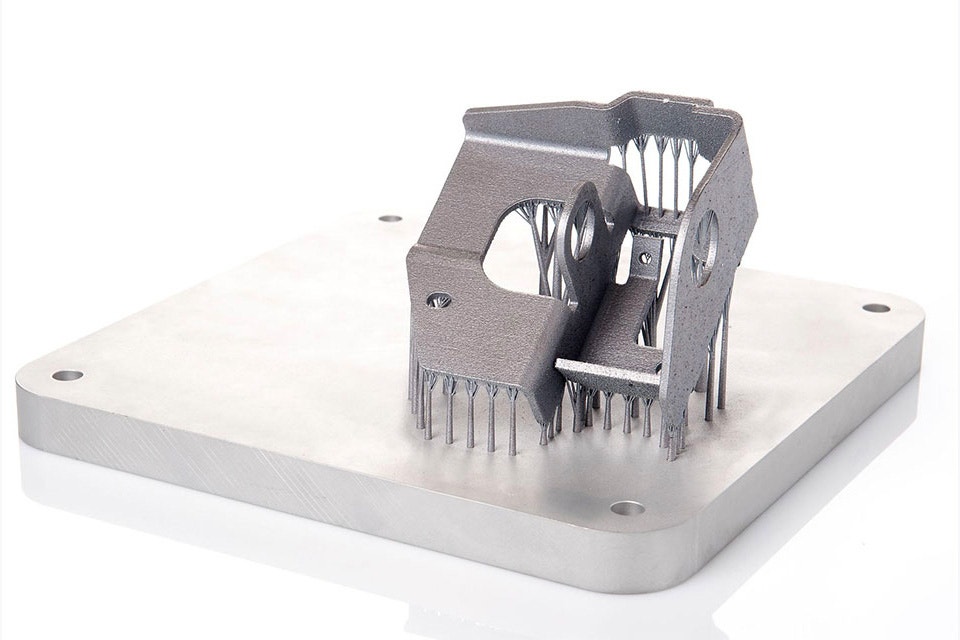

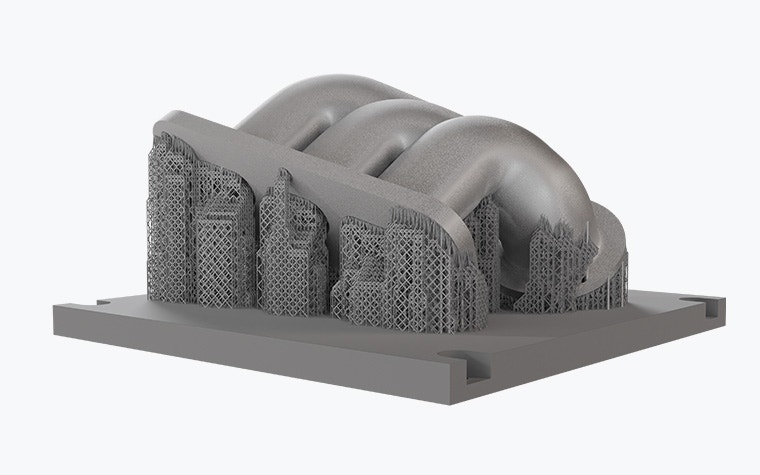

Metal 3D printing

Reduce costs and staff-hours by semi-automating the support generation process for your metal 3D-printed parts with Materialise e-Stage for metal. With this module, you can cut time spent on data preparation, support design and removal, and finishing while reducing human error. Avoid costly build crashes and ensure successful prints every time.

Resin 3D printing

Lower labor costs and realize other significant savings in your resin production with Materialise e-Stage for resin. With this module, you can cut time spent on data preparation, support design and removal, and finishing while dramatically lowering your part’s resin consumption. Generate needle-thin supports where required and use an open diamond-shaped structure to drain and recuperate raw material.

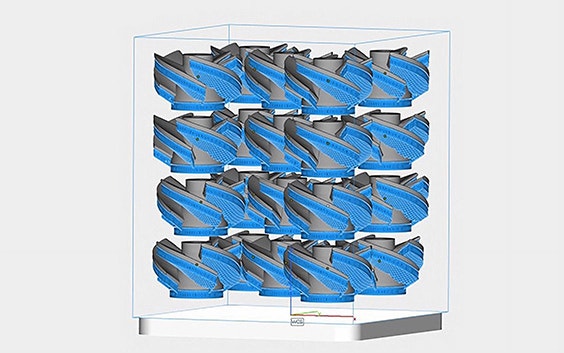

Binder jetting/electron beam melting

Simultaneously nest parts with support for optimal stacking.

Learn about Support Generation

Discover how to get started via our Academy, and get answers to all your questions from customer support.