CASE STUDY

Successfully Doubling Production Numbers in One Week: How CommScope Did It

CommScope has been working with 3D-printed parts since 2002. Their additive manufacturing (AM) department has grown from ordering parts through Materialise to developing in-house printing operations. As operations grew, they sought out ways to boost productivity. With the help of Magics and its Sinter Module, the CommScope team was able to do just that ― doubling production numbers in one week.

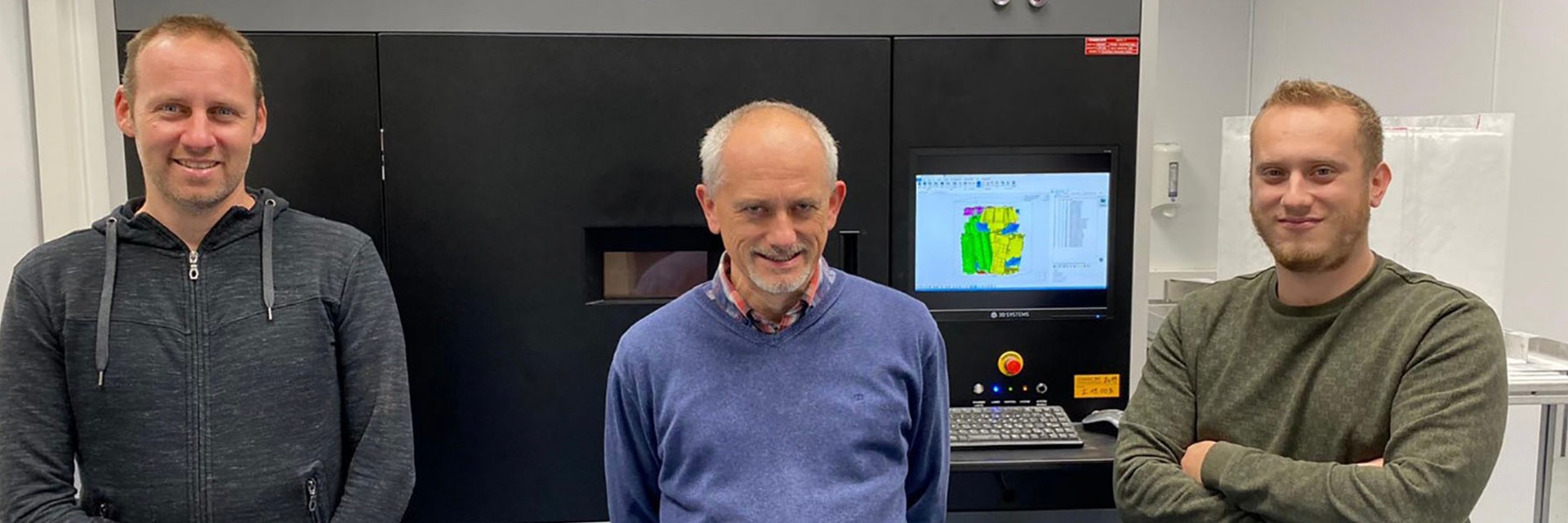

CommScope is no stranger to 3D printing. Their Belgian team has been 3D printing prototypes for their R&D department for over 18 years. With these prototypes, they validate parts to help companies build and manage their wired and wireless networks.

As the years went on, their use of additive manufacturing grew. And so did the partnership between CommScope and Materialise. Eventually, CommScope brought production in-house as well, so they turned to Materialise for 3D printing software solutions.

Even as CommScope began printing parts on their own, they continued to receive manufacturing support from Materialise — ordering parts when they are too large for their machine or if an application calls for a different technology or material from what they have available.

“Materialise is the best support we have here in our 3D printing department. ”

— Joren Schurmans, 3D Printing Technician, CommScope

In 2019, CommScope brought an SLS machine into their production and implemented Materialise Magics as their tool for data and build preparation. Overall, Magics brought ease of use and increased productivity to their workflow. But when they added Magics Sinter Module to their toolkit, they experienced game-changing productivity.

One tool to double production

Before using Sinter Module for their SLS prints, CommScope was nesting their parts using basic software included with their machine.

“We had only used the previous software for about two weeks,” shares Joren Schurmans, 3D Printing Technician at CommScope. “We quickly realized that this tool wouldn’t provide the functionality we needed for our process.”

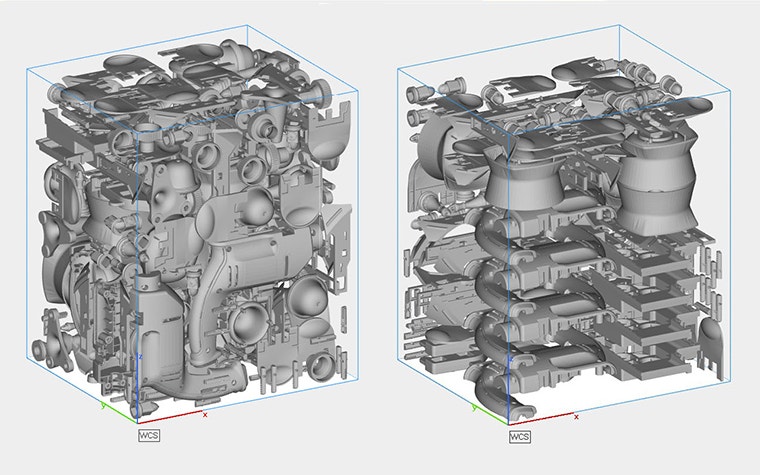

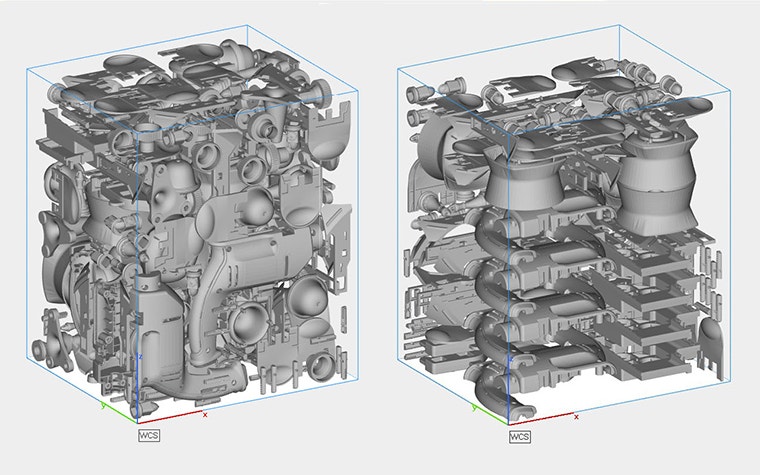

“Our previous software used bounding boxes to nest the parts,” elaborates Peter Stockmans, R&D Engineer at CommScope. “Large parts took up too much space, and our smaller parts weren’t optimally placed around them. The software often acted unpredictably.”

Magics Sinter Module also offers a bounding box nester as a quick nesting option, but the geometry-based alternative with manual positioning options was the better fit for CommScope. With this, they could optimize builds by manually placing larger parts first and then relying on the program’s automatic, geometry-based nesting to quickly fill in the gaps with smaller parts. This offered much denser nesting, and with the introduction of Sinterboxes, they had the added benefit of keeping small parts together for easy recovery after the print is complete.

The improvements in their SLS production were rapid and significant. The team only needed half a day to master the Sinter Module’s workflow. From then, they optimized their printing workflow so much so that in just one week, they doubled their production numbers.

“Overall, we’re working with a much higher efficiency now that we’re using Magics. Preparing parts and reporting is much less time-consuming, giving our team more time to work on other projects," says Joren.

“With the reporting tool, we can add up the costs for an entire build with 300-400 parts in just two minutes,” explains Peter.

An extensive, strategic partnership

Materialise and CommScope have worked together for over 18 years, and this collaboration has grown into one where CommScope can rely on Materialise to support them in many instances. What began as a manufacturing relationship has evolved into one where CommScope feels confident turning to Materialise whenever they’re looking to improve their AM strategy.

“Any time we reach out to Materialise for assistance, we get detailed responses from the support team with clear explanations and even screenshots to help us resolve the issue. We also attended a full-day Magics training course which was a huge help for us to learn about the new features,” says Joren. “Materialise is the best support we have here in our 3D printing department.”

Share on:

This case study in a few words

Communication network infrastructure

Materialise Magics

Sinter Module

Improve the nesting process to increase productivity