EXPERT INSIGHT

30 Years of Innovation: Stable and Durable FDM Is Ideal for Aerospace

Since arriving at Materialise in 2003, fused deposition modeling (FDM) has proven to be a highly reliable addition to our offering. Discover why the strengths of FDM lead to durable prints, and why it’s the trusted go-to for aerospace and other industries that rely on certified manufacturing.

In 2020, we celebrated Materialise’s 30th anniversary. Our 30 Years of Innovation blog series highlights some of the different 3D printing technologies that have helped our customers achieve their ambitions over the years and shows that there is no one-size-fits-all approach to 3D printing. This time, it’s the turn of fused deposition modeling (FDM).

One major factor contributing to FDM’s reliability is the durability of the materials: the range of materials available on FDM is not only extensive, but includes some plastics that are known for their excellent properties, including flame retardancy, handling heavy loads, thermal resistance, and more. Another major factor is the technology itself: it’s a stable technology that lets us repeatedly produce the same parts and, from these iterations, achieve a high level of accuracy.

Our Production Manager for FDM, Christof Van Poucke, says, “FDM is overall a great technology to work with. It’s fast, which is great for both prototyping and end-use parts in low quantities of smaller sizes. With our Fast Lane service, your lead time for ABS could be as low as 48 hours, or four days for our standard service.

“And the durable materials that work with FDM mean that you can have end-use parts with excellent properties. Plus, when you have a design and today you want to print it in polycarbonate, but tomorrow you want to print it in Ultem to be flame retardant, it’s actually quite easy to just switch from one material to another on the same machine.”

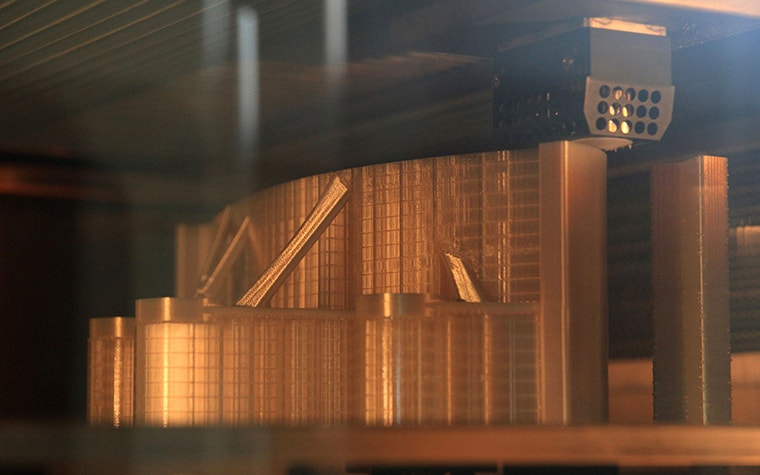

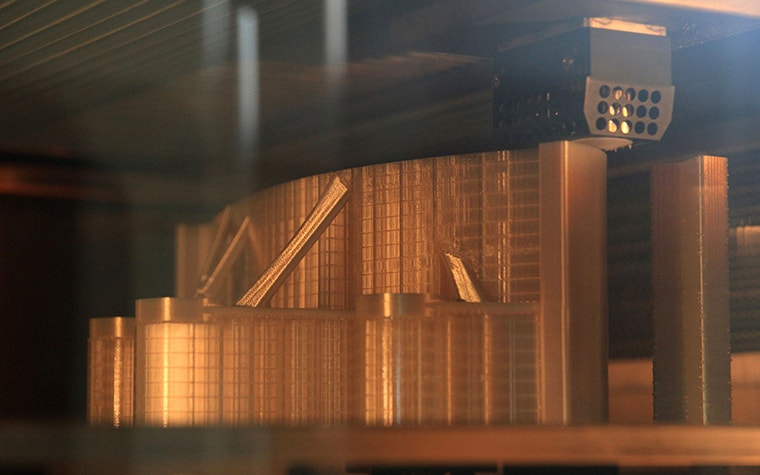

Though FDM machines are one of the most common technologies for home printers, customers turn to Materialise to reach the next level of 3D printing. Our commercial-grade machines provide finer detail, larger prints, and better quality.

Also, Materialise’s knowledge resources mean that we can offer customers more than just a print: “Materialise has decades of experience in data prep and designing for 3D printing. This means we work with customers to make parts better suited for 3D printing, such as combining parts to make one assembly-free part or reducing bulk to make prints more lightweight while maintaining the same strength. We have additional features at our fingertips too, such as adding infill structures and strengthening ribs, adjusting wall thickness and contour lines, and other customization techniques,” says Christof.

Excellent match for certified manufacturing

Ensuring a consistent, high-quality 3D print every time is essential in industries such as aerospace, automotive, and locomotive in order to protect passengers. That is why there are a series of certifications that companies have to acquire and maintain to become a supplier.

The three most important aspects of certified manufacturing are reliability, repeatability, and quality. FDM checks all three of these boxes, making it an excellent match.

“FDM is overall a great material to work with. It’s fast, and the durable materials that work with FDM mean that you can have end-use parts with excellent properties. ”

— Christof Van Poucke, Production Manager for FDM, Materialise

This certified manufacturing process has a chain of rigorous steps. There are a number of process outputs which need to be examined, including tensile, density, and dimensional crosses. Moreover, these need to be examined over time and according to the machine. The settings on the machines themselves are controlled by a fixed set of parameters.

As Christof puts it, “Change control is very important when it comes to certified manufacturing. Whenever we make any adjustments on the machines, we need to do a complete validation of the machine again before it can be up and running. We test if the parts are as strong as before and if the dimensions are still the same. So there’s a lot of checking ‘behind the scenes’ so to speak.”

Then there are environmental conditions that could also affect the parts. “We continuously monitor the humidity and temperature in our FDM rooms. If we go beyond a certain threshold, we know that the parts will not pass our quality requirements,” says Christof.

Aerospace certifications

FDM’s reliability, ability to control parameters, and range of certified materials make it ideal for certified manufacturing, which the aerospace industry relies on.

In addition, Materialise is certified under EN9100 and EASA Part 21G, meaning that we are an approved manufacturer of flight-ready aerospace parts. Both certifications are a credit to the Materialise quality management system, with a special emphasis on documentation and traceability for aerospace.

FDM prints are an excellent match to meet the aerospace industry’s needs.

“Full traceability is extremely important when it comes to certified manufacturing. We need to approve the suppliers we get our raw materials from, and each material batch is inspected upon arrival to check whether it is within the defined specifications. If it’s not, then we need to put it in quarantine and send it back,” says Christof.

All of these steps require diligent logging of all the details on the production of each specific part, which is done through Materialise software Streamics. The data is stored for 15 years in case, for example, a supplier recalls a material batch. This measure would allow us to track all parts produced from that specific material batch and notify the customers.

Collaboration with Airbus

“Airbus first came to Materialise for additive manufacturing of flying parts back in 2015. FDM was the best match in terms of technology because of its process stability and repeatability, in combination with high-grade engineering plastics, such as Ultem,” says Gert Brabants, Project Manager for Aerospace.

One of the important reasons why Airbus turned to additive manufacturing is the small series production. According to Gert, “If you want to use injection molding for manufacturing, you produce around the scale of a thousand parts in one month. If you only need a few parts a month, additive manufacturing makes sense because you do not need to warehouse the extra parts and you don’t have the typical changeover costs in your production line.

“From a supply chain point of view, it also makes a lot of sense. Instead of managing hundreds of suppliers producing a few parts in small series, a company like Airbus can produce hundreds of parts on a flexible production line, like additive manufacturing offers.”

FDM has yet another advantage when it comes to aerospace, which is a short lead time. “Each hour that a plane is grounded for repair and maintenance can cost up to €100,000. That means that if there are parts that need to be replaced, they need to be guaranteed to be delivered by a very specific time. That way the crew has the part in hand and can make the necessary adjustments quickly,” says Gert.

Certified post-processing

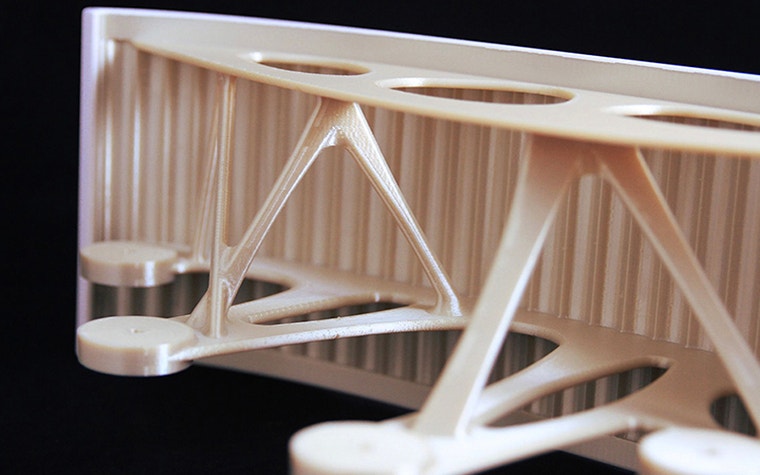

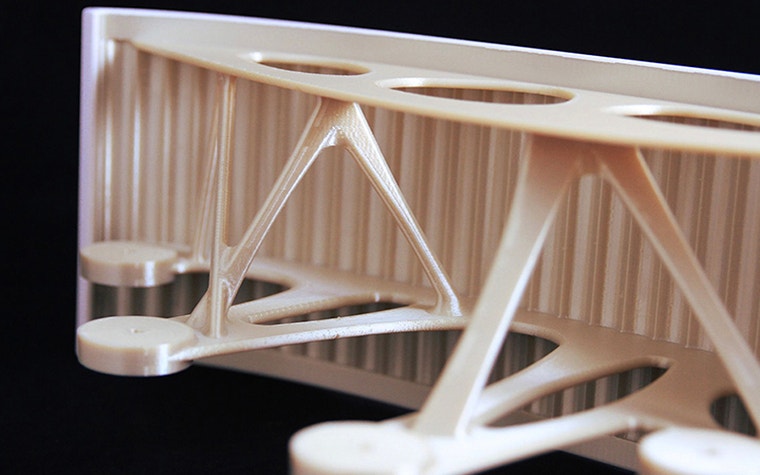

Since working with Airbus , Materialise has 3D-printed parts that are both visible to passengers and hidden from view. For example, Materialise has provided thousands of brackets and cable guides for several aircraft families, and in 2018, Materialise manufactured the first-ever 3D-printed visible part on an Airbus commercial aircraft.

“When we actually start designing for AM […] not only cost savings for small series and supply chain benefits, but also weight savings, part integrations and increased design complexity can be realized without increasing costs.”

— Gert Brabants, Project Manager for Aerospace, Materialise

The part was a spacer panel for the overhead luggage compartment. Not only was Materialise able to deliver the customized part quickly at a cost-effective price-point for small series, but 3D printing could also make the part 15% lighter.

“It’s one of the first examples where we really used all the benefits additive manufacturing can offer. When we actually start designing for AM, we can exploit much more of its potential. Not only cost savings for small series and supply chain benefits, but also weight savings, part integrations and increased design complexity can be realized without increasing costs,” says Gert.

And one of the other major factors? The post-processing of the part could be done at Materialise. Just as the other aspects of manufacturing parts for aerospace are highly regulated and need to fall within tight specifications, so do the post-processing steps.

According to Gert, “Due to the specific fire regulations for aerospace, painting parts needs to be done according to a high standard, where micrometer accuracy is required from our painters. What this does is adhere to the strict flammability and toxicity standards required for aerospace parts, while offering the same look and feel as any other part of the aircraft interior.”

FDM’s reliability and low lead times along with Materialise’s certification, expertise, and end-to-end manufacturing have made it a trusted technology for certified manufacturing.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.