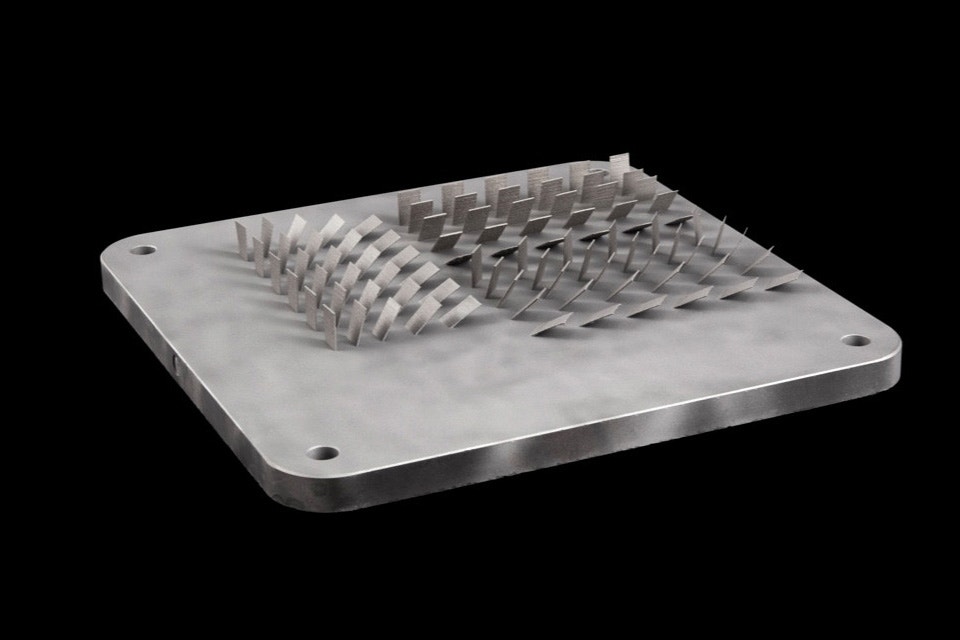

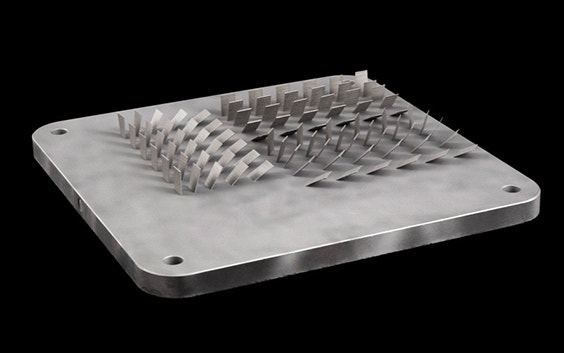

Materialise Process Tuner

Automated and streamlined additive manufacturing process development

Process development is critical when introducing new printers or machines into your additive manufacturing (AM) production, but it’s often complex and time-consuming. With Materialise Process Tuner, you can turn process development into a streamlined workflow that eliminates redundant tasks; automates build strategy application and labeling; and includes an embedded database to track and organize experiments.

Benefits

Reduced costs

Leverage automation to minimize manual effort needed to set up tests as well as simulation and analytic tools to reduce the number of parts to be printed.

Reliable, repeatable processes

Increase productivity in your R&D teams thanks to added traceability and standardization across different departments working on the same project.

Faster time-to-market

Shorten the experimental phase by reducing the number of tests needed and, therefore, the time spent completing them.

Advanced innovation

Streamlined processes enable a simpler, faster, and more affordable introduction of new or improved offerings, empowering you to bring your solutions to the next level.

Features

Guided, automated workflows

Experience simplified process development. Automate the generation of samples and fly through the steps with a clear process defined by the software.

Insights for determining experiments

Clever statistics, simulation, and AM intelligence identify the most advantageous experiments to complete, so you don’t waste time.

Embedded database

The software automatically stores all data generated during experiments to simplify data examination.

Flexible usage

Process Tuner is a cloud application with private setup options, simplifying collaboration and providing easy access to data during process development.

Learn about Process Tuner

Discover how to get started with Process Tuner via our Academy, and get the answers to all your questions from customer support.

You might also like

Slice and send jobs to 3D printers based on machine-specific strategies or optimize custom scan path strategies with our software development kit.

Plan and manage the entire AM process to maximize throughput, optimize capacity, and gain complete visibility across your operations.

Track non-conformances and CAPA reports to drive continuous improvement and meet regulatory compliance.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.