Materialise 3-matic

Design optimization software

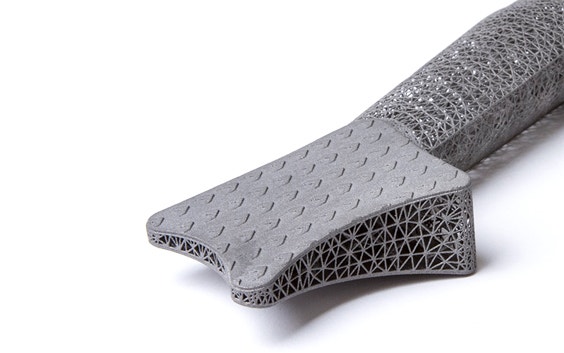

3-matic enables you to clean up rough data from a CAD design, topology-optimized model, simulation, or scanned data by making design modifications on the mesh level. Enhance models for 3D printing with 3D textures, lattice structures, conformal structures, and scripting automation to easily create ranges of validation samples — improving your overall productivity.

Benefits

Freedom of design

With 3-matic, you can fully personalize your products and create models that are impossible to produce with traditional manufacturing methods.

Save time and costs

Leverage 3-matic’s tools and the Lattice Module to create designs that outperform solid parts and require less material, reducing costs and printing time.

Features

Post-topology optimization tools

Redesign rough surfaces to prevent complicated freeform modeling work and possible stress concentrations for FEA when transitioning from mesh to CAD.

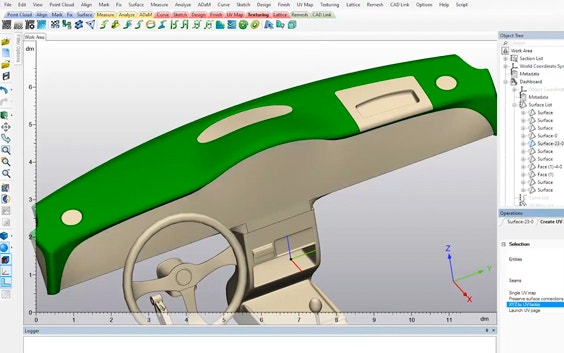

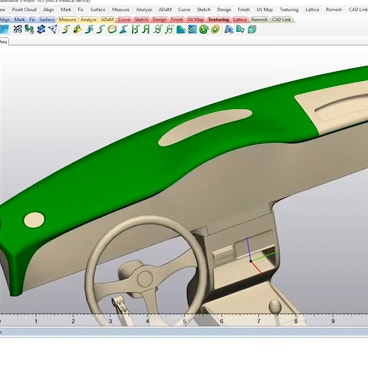

Textures, patterns, and perforations

With the Texturing Module, you can apply textures, patterns, and perforations to complex 3D shapes within an STL file to add functionality or an aesthetic dimension.

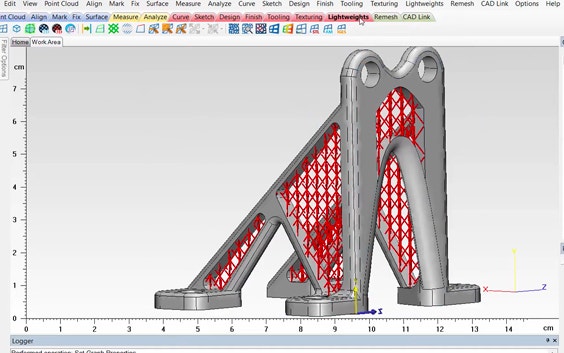

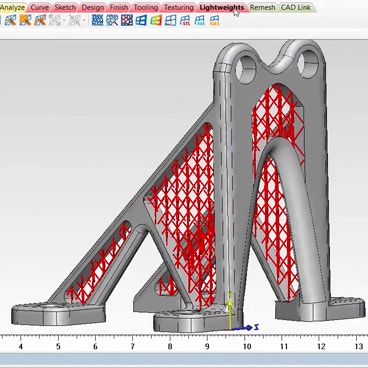

Lattice, conformal, and porous structures

With the Lattice Module, you can create printable internal and external structures that add extra strength, cushioning, and porosity or simply reduce the weight of your design.

Convert mesh to CAD

Easily convert a mesh file to a CAD file format with the CAD Link Module. This tool recognizes analytical shapes in your part and generates a fully parametric model without designing from scratch.

Automate your design workflow

Use the Scripting Modules to automate tasks and process files with more speed and control. It comes with Python API, access to 3-matic objects and features, and a comprehensive toolkit.

Learn about 3-matic

Discover how to get started with 3-matic via our Academy, and get the answers to all your questions from customer support.

System requirements

Get inspired

You might also like

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Bridge the gap between CAD software and 3D printers by importing nearly all standard CAD formats.

Nest parts quickly and efficiently to maximize build capacity, protect small pieces, and reduce human error.