Material

Composite Materials

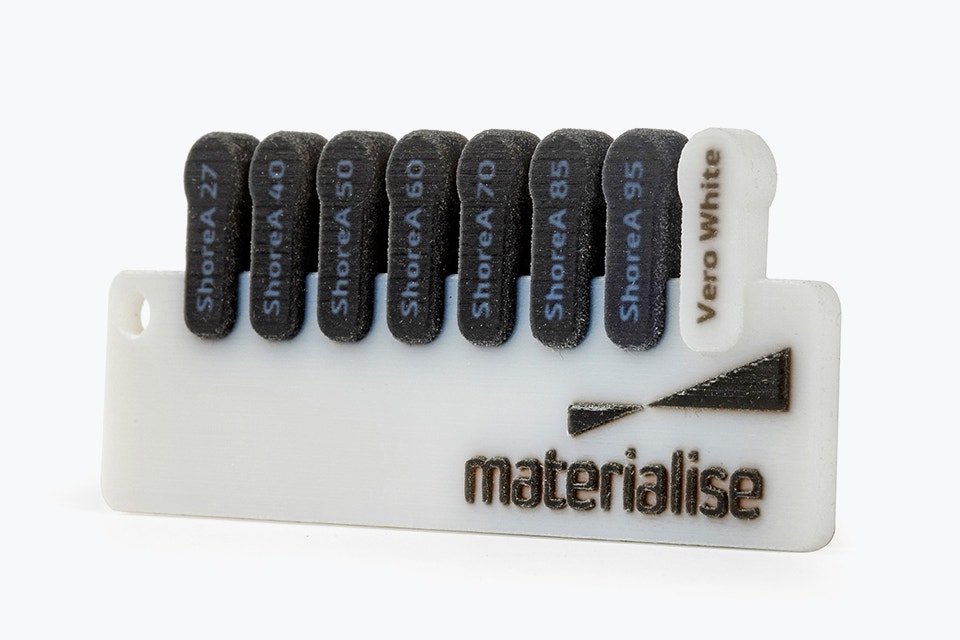

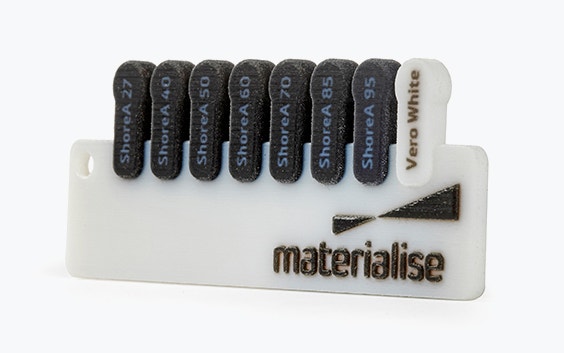

Agilus provides superior tear-resistance and elongation at break, making it ideal for prototypes of rubber components like grips, seals, and non-slip surfaces. This range of composite materials blends Agilus with VeroWhite to offer different Shore values and mechanical properties, providing options for a variety of applications.

Technical specifications

| Maximum part dimensions | 350 x 250 x 100 mm |

| Standard accuracy | 0.1 – 0.3 mm (varies depending on geometry, part orientation and print size) |

| Layer thickness | 0.032 mm |

| Minimum wall thickness | 1 mm |

| Minimum detail size | 0.5 mm |

| Interlocking or moving parts | Yes |

| Internal channels | No |

| Surface structure | Slightly rough, matte surface |

Datasheet

| PARAMETER | VALUE | UNIT | METHOD |

| ASTM D412 | 0.5 – 1.5 | MPa | |

| ASTM D412 | 150 – 170 | % | |

| ASTM D2240 | 28 – 40* | Shore A | |

| - | Black |

Primary material: VeroWhite, secondary material: Agilus Black

Actual values may vary with build conditions and in relation to the part’s geometry and orientation.

*Please note that PolyJet composite materials are easier to bend than rubbers of the same Shore A hardness.

Please get in touch with our team for more information and guidance.

Finishing degrees

The right finish can transform your print into a product. Explore the post-production finishes we offer for this material. If you have any questions or special requests, get in touch with us.

Train and learn

Get more from your next project with helpful resources dedicated to composite materials and PolyJet.