CASE STUDY

Lighter, Faster, Cheaper: Manufacturing Flight-Ready Parts for 328 Support Services

As the type certificate holder of the Dornier 328 aircraft — originally produced by Fairchild Dornier — 328 Support Services handles the maintenance, modification, and refurbishment of the fleet of around 180 operational Do328 aircraft around the world. In preparation to relaunch serial production of this twin-turboprop engined regional airliner, 328 worked with Materialise to make plastic spare parts lighter, cheaper, and faster to produce.

The challenge

Make short production series more affordable

Commercial planes take years to hit the market, following painstaking design processes and rigorous quality checks: so rigorous that the plane is likely to be in good flying condition for 25 to 30 years. Throughout this lifetime, efficient management of the production and availability of spare parts play a crucial role in reducing a plane’s downtime — and in an industry where a grounded plane costs thousands of euros every day, time really is money. In preparation to relaunch serial production of the Dornier 328 aircraft, 328 Support Service’s Supply Chain and Engineering departments were in a constant process of streamlining manufacturing processes and identifying cost drivers.

When production runs are very short — as is often the case for aftermarket parts — a conventional manufacturing method like injection molding doesn’t make financial sense because the cost per part is very high. And as well as the initial investment in tooling, those tools need to be stored, incurring ongoing expenses. Keeping large stocks of spare parts is wasteful too — it’s impossible to predict when they will be needed, and there’s a risk they become obsolete while still on the shelf.

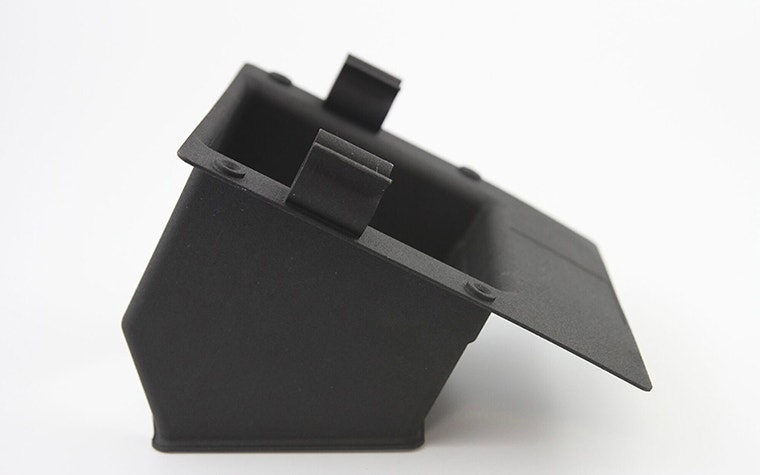

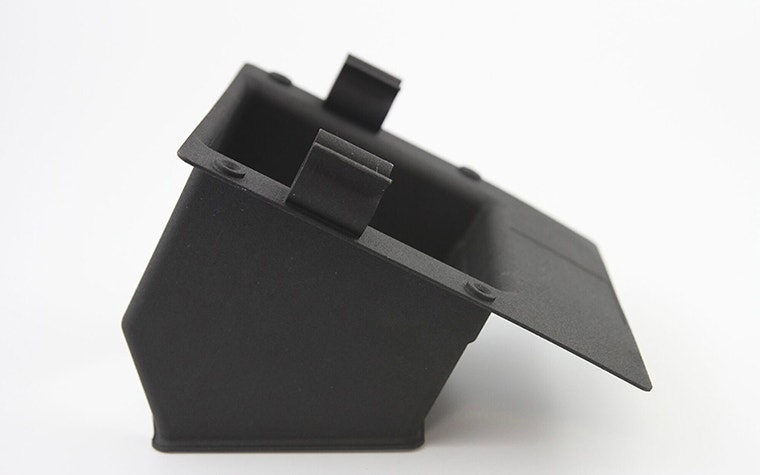

The company also saw the potential for cost savings by using a different material for their spare parts — instead of the phenolic resin laminate they had been using, 328 was looking to make the switch to something lighter and more cost-efficient.

What they needed was a way to make short production series more affordable, while ensuring fast turnaround and flexibility in the choice of materials.

The solution

Additive manufacturing for aerospace

While the most commonly stated benefit of additive manufacturing for the aerospace industry is the freedom of design and innovative engineering, this wasn’t the main draw for 328 — the spare parts in question are relatively standard and straightforward, and because they are already certified for aeronautic applications, they cannot be altered without going through a re-certification process.

“3D printing lets us pick parts from a virtual shelf.”

— Volker Liedloff, Team Leader Interior Engineering at 328 Design

Instead, it was aerospace 3D printing’s reliable, cost-efficient, and timely production that won 328 over. And by choosing Materialise’s aerospace manufacturing services, the company could be assured of flight-ready parts that meet the most stringent requirements.

“Parts produced for the aerospace industry have to conform to very strict standards. And that’s where Materialise’s certified manufacturing comes in,” says Erik De Zeeuw, Aerospace Market Manager at Materialise. “Materialise holds EN9100 and EASA 21.G certifications that qualify us to manufacture end-use parts for the aeronautics and aerospace industries, making us the perfect fit for 328.”

The result

Aftermarket plastic spare parts that are lighter, cheaper, and faster to produce

By partnering with Materialise, 328 achieved the optimal balance between spare part availability and cost, receiving flight-ready parts on demand from Materialise.

“3D printing lets us pick parts from a virtual shelf," says Volker Liedloff, Team Leader Interior Engineering at 328 Design. “We would no longer run the risk of produced spare parts becoming obsolete too soon or of keeping tools for parts with very low demand.”

After receiving a new part design for 328, engineers at Materialise conduct feasibility checks for 3D printability and set up processes for production and quality inspection. Once the printed parts are approved by 328, the process is consolidated; Materialise issues a First Article Inspection and Form 1 accreditation. The parts are then printed on demand at Materialise using a flame-retardant polyamide material (PA 2241 FR). Each of the steps follows strict regulations in line with aerospace certifications and culminates in production-certified 3D printed parts that are ready to be installed in a plane.

“When 328 needed a part on a very short notice, we were able to produce it within the week,” adds Erik.

On all counts — affordable, short production runs, fast turnaround, and light materials — additive manufacturing has proven to be the way forward for 328 Support Services and the Dornier 328 aircraft.

以下で共有する:

上記CASE STUDYについて

328 Support Services

Aerospace

Manufacturing services

Selective laser sintering

PA 2241 FR

Affordable short series production