インタビュー

Analyzing the Importance and Impact of Sustainability in AM

Recently, sustainability has been top of mind for companies and consumers. And additive manufacturing (AM), also known as 3D printing, is gaining prominence as a sustainable alternative to traditional manufacturing in certain situations, such as rapid prototyping, spare parts, and mass customization. But are we fully aware of the impact AM can have on society, and how sustainable is it? We spoke to Sherri Monroe, Executive Director of the Additive Manufacturer Green Trade Association (AMGTA), and Leen Kuijken, Head of Sustainability and Corporate PMO at Materialise, to explore the relationship between the two.

Hi Sherri and Leen. We previously spoke about how companies can implement sustainability into their operations, but why is sustainability so important in AM?

Sherri: Well, sustainability is important for a couple of reasons. In any type of manufacturing, the conversation will naturally come up. Either certain companies will be personally motivated, or their customers and employees will drive the demand. Something to consider is that while AM has the potential to be sustainable in various ways, it isn’t, by definition, more sustainable.

One advantage we have for adopting more sustainable practices into AM is that while AM has been around for a while, our thought process around how we work with AM is fairly new. There isn’t a fixed way of doing things for the past 30 years, the ground is already unsettled, so there’s no chance for inertia. We have the potential to start doing things the right way — a sustainable way. We can keep what makes sense while avoiding pitfalls like legacy infrastructures that may already be in place, which is apparent in traditional manufacturing. As more and more companies adopt this mindset and move forward, sustainability will be a key part of this progression and will offer businesses an incredible opportunity to thrive.

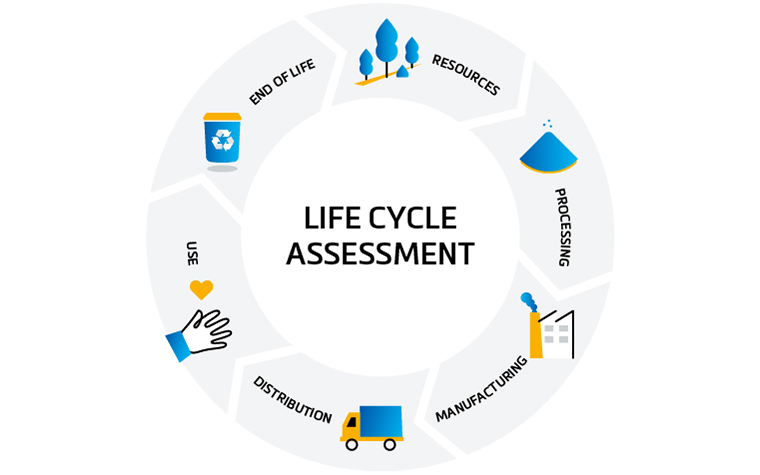

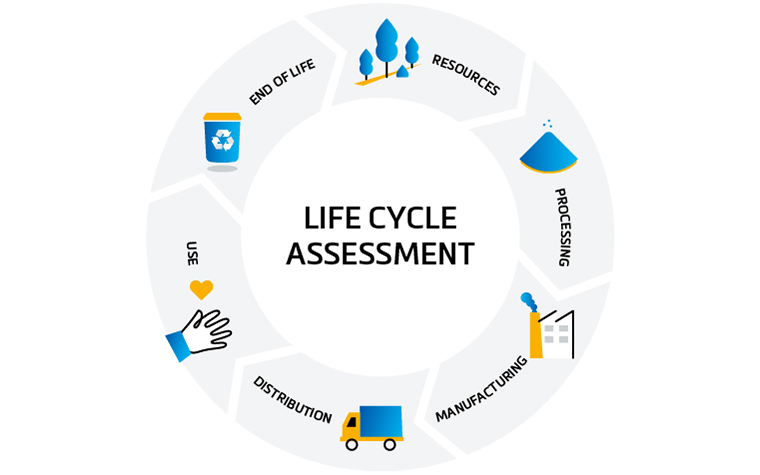

Leen: I fully subscribe to these points. I also think it’s incredibly important that as this mindset is new, we (i.e., the industry) should take this opportunity to continue investing in research and data. As we lack so much data, there are many examples where we don’t know how sustainable a particular product or process is — and that’s crucial because sustainability is important in all walks of life and across sectors. We need to continuously invest in life cycle analyses (LCAs), create and maintain partnerships to gain further insights, and figure out how to support each other to tackle key challenges. For example, how can we reduce energy, use more sustainable materials like recycled powder, and what alternative materials can we invest in or investigate in the future?

Sherri: Exactly, and to pick up from Leen’s idea about data, we (the AMGTA) have different types of audiences; the AM audience that’s new to sustainability and the sustainability organizations that are unaware of AM in general. We want to create a dialogue with both groups because both see each other’s potential, but they don’t know how to utilize their respective qualities. Therefore, we can expand together by collaborating. But both groups need the confidence that there’s real merit in the other’s capabilities, and independent data, reviews, and LCAs can only help achieve this. Regardless of whether the result is positive or negative, the information can be analyzed and transferred to other projects. If companies and organizations are going to spend hundreds of thousands or maybe millions of dollars or euros on AM and sustainability, they want some comfort that there’s real potential here.

Leen: I agree. Fortunately, the AM business is now taking sustainability more seriously. In the past, the claim was that AM was “green,” and this was seen as a synonym for sustainability. AM allows for on-site production, therefore, fewer transport emissions. And it allows for lightweight structures, reducing the weight of vehicles and planes — again leading to lower emissions. However, while it’s an easy conclusion to make, it’s also an incorrect one. Research data and independent analysis, such as LCAs, show whether a process is sustainable. It’s vital that the industry takes responsibility and is brave enough to show when a method is successful regarding more sustainable production, or when alternatives are better and publishes these results. Society is waiting for companies and the industry to take responsibility, pinpoint where we can improve, and make the next big step forward.

How seriously is the AM industry taking sustainability?

Leen: The AM industry is becoming more sustainable, especially since organizations (like Materialise) are saying that a process (like 3D printing) is not just sustainable per se; you need to use it correctly and set yourself up in a sustainable way. For example, it’s no secret that AM processes are very energy-intensive. Emissions in AM production come from the production of the powder and the electricity used in the printing process. It’s important that we investigate these factors and that we are transparent about them. Once you know the biggest factors, you can then take the correct actions to decrease your emissions — e.g., by reusing powder more often and switching to renewable electricity.

Sherri: I agree. I attended a conference in Munich, and every panel discussion mentioned sustainability, even though that wasn’t the subject in question. Everyone is trying to figure out how sustainability fits into their business model and where the opportunities present themselves. Personally, that’s encouraging. However, I don’t think companies will have a choice. Customers, employees, and society are increasingly demanding this right now. The pandemic and other global events in the last couple of years have pushed this to the front of people’s minds when it might not have been three or four years ago.

Regarding environmental sustainability, companies and organizations usually discuss CO2 and lowering greenhouse gas (GHG) emissions. How important is this? Are there other aspects they should also be addressing?

Leen: Although I mentioned CO2 before, sustainability is much more than that. That’s a point we must make and continue making again and again. Next to CO2, sustainability has environmental aspects, like examining the toxicity of products and materials, and there’s also social sustainability. How do we deal with people in the supply chain, where and how are the materials produced, and do our suppliers have policies to protect people (e.g., anti-slavery and conflict mining)? These are just some topics that touch on totally different parts of sustainability, and it’s important to stress this.

Sherri: Leen makes an excellent point because sustainability is much bigger than just the usual CO2 and GHG argument. Its social impact is enormous — we should focus on mitigating the negatives and amplifying the positives. For example, when you examine the medical applications of 3D printing, creating custom-made implants or prosthetics instead of a one-size-fits-all approach, how do you put a value on that? And looking at other areas to consider in terms of environmental sustainability, like renewable energy, the production process, etc., are just as important. Many factors are difficult to quantify and put a financial value on, but it’s significant for the people impacted.

What are some common misconceptions about the sustainability of AM, and how can companies avoid them?

Sherri: One misconception is that printing requires or uses less energy. This is not necessarily true. If you look at the powder production process, it’s very energy intensive, especially to produce a viable powder — certain aspects like that need to be factored in. For an LCA we’ve just wrapped up and will release soon, we discovered that it was hard to define whether the AM process was sustainable during the production phase. However, there is much more to assess beyond the actual production phase. The idea that AM is sustainable simply because there’s less scrap material compared to subtractive manufacturing is not the case: it depends on what you’re doing. This is becoming more widely understood, and companies now realize there is more to the story than just AM automatically means sustainable.

Leen: The initial optimism or view that “AM must be sustainable” is now over. Only a certain percentage of kilograms of powder ends up being used in the final product. This is important information that people don’t come across. People assumed (and some still do) that things just magically happen, and you print what you need. Many people have a gap in the technical details, and it’s an easy misconception to make. But that’s changing with more measurements and data.

AM is normally associated with design freedom, but how can AM design, and AM in general, influence sustainability?

Leen: The classic example is that AM produces lightweight and more economical parts. But as Sherri mentioned earlier, AM offers functionality and personalization suitable for certain industries and applications. You can combine several functionalities into one piece to improve a part’s performance.

Sherri: Not to mention, design freedom is about removing constraints. This can be the design aspect, e.g., making parts more lightweight; however, design freedom is also related to how it’s produced. Can it be manufactured using different energy methods, such as renewable energy? Or can we compensate for the energy usage by shipping the part to be assembled? We always assume that every part needs to be manufactured in the same area, but maybe we can rely on more mobile production. This sort of critical thinking can be applied to areas like the material selected, where it’s sourced, the afterlife of a product, etc. Keeping an open mind on things we can improve and performing LCAs feed into the environment of pursuing new ways of working.

Materialise and AMGTA have both conducted LCAs recently to indicate how sustainable AM is compared to other manufacturing processes. How important is transparency in the industry, and are these studies part of your long-term strategy to evaluate AM’s sustainability credentials?

Sherri: Transparency opens us up to scrutiny and makes us vulnerable. But it’s significant for a couple of reasons. The first is that it provides credibility to what we’re doing. And the second is that if you show everything, the good and the bad, you provide valuable lessons you’ve learned along the way. Lessons from one LCA could be applied to different scenarios and applications in other industries — so the information is viable on a broader scale.

We’ve been working on multiple LCAs (four are underway, and two are nearing completion). One is about an airplane bracket, and the other looks at binder jetting, mainly parts that go into air conditioner compressors. For the binder LCA, we approached it in two phases. Phase one analyzes reproducing the part using binder jetting, and phase two looks at redesigning the same part to add improvements like making it more lightweight. Another LCA we’re excited about, particularly for an AM audience, is the poly jetting onto fabric for the fashion industry. The fashion industry is notorious for producing wasted material in landfills, and the environmental impact is terrible, so we see huge potential in this scenario.

We’re constantly looking at ways of working with our members on joint LCAs or having their LCAs independently reviewed. There are some great opportunities and projects in the pipeline. We’ll keep looking at ways to engage with our members and encourage them to do more research, whether that’s doing more research themselves or providing data for research.

Leen: Apart from our LCA with BASF on the sustainability of AM processes regarding the production of midsoles in a sports shoe, we’re also working with a consulting company on a new LCA next year. This will look at the personalized insoles that we put on the market and compare 3D printing methods with the traditional foam method. We print in Bluesint, or recycled powder, but is it more sustainable to print compared to the traditional method? It’s exciting research, but we’re showing our vulnerability, too. And while LCAs are not our core business, partnering with others with expertise in the field, being transparent, and showing a little vulnerability by spreading information (warts and all) only benefits the industry.

Finally, you’re both women in senior positions at companies/organizations shaping the AM industry. What advice would you give to the next generation and women wanting to make the AM industry more sustainable?

Leen: My advice for women and men who want to make AM increasingly more sustainable is to lead by example and make your company lead by example. Show that the topic is close to your heart and take the initiative. Search out like-minded colleagues, put sustainability on the table for debate, and make your voice heard. And to leaders, sustainability is rapidly becoming extremely important for all young (and mature) people, whatever position they enter in your organization, so take notice.

Sherri: Exactly. And I’d stress that it’s essential for young people to go into fields like manufacturing and engineering, especially women, as they are underrepresented. There’s a wonderful opportunity now as this is untilled ground ready to be nurtured. This is all new, and there’s so much room to flourish and innovate. Companies should employ a diverse range of people, regardless of age and gender.

These people bring fresh ideas and experiences. One hundred years ago, we didn’t know what the next mountain would be. Now we know that sustainability is our mountain, and we need all the ideas we can get. And these ideas and opinions will not always be aligned, and that’s OK. Actually, it’s crucial because more diversity will mean we find solutions supporting us to overcome this huge challenge.

Interested to hear what Sherri and Leen have to say about the importance of partnerships and how sustainability roadmaps and best practices can help you reach more sustainable outcomes in all parts of your business? Take a look at our previous interview with them.

以下で共有する:

経歴

Sherri Monroe

経歴

Leen Kuijken