CUSTOMER STORY

Exploring Additive Manufacturing Opportunities: Optimizing Production with Hyundai Lifeboats

The value of additive manufacturing (AM) is well established at this point. It’s used regularly in even the most demanding industries, such as healthcare and aerospace, and 90% of manufacturers believe it’s essential to become future-proof. But the journey to finding success in AM is no simple task. Materialise Mindware, our 3D printing consultancy team, outlined the various steps to steer customers through this journey. Discover how they guided Hyundai Lifeboats through the first phase, Explore, and developed custom jigs and fixtures to optimize their production of lifeboats.

The roadmap to AM success

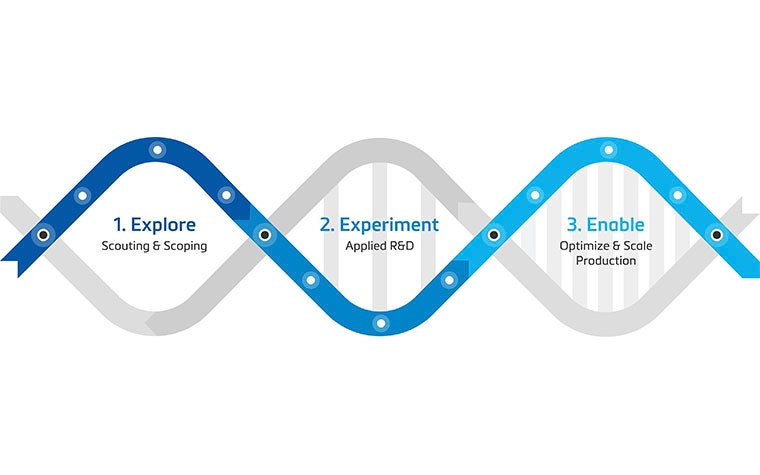

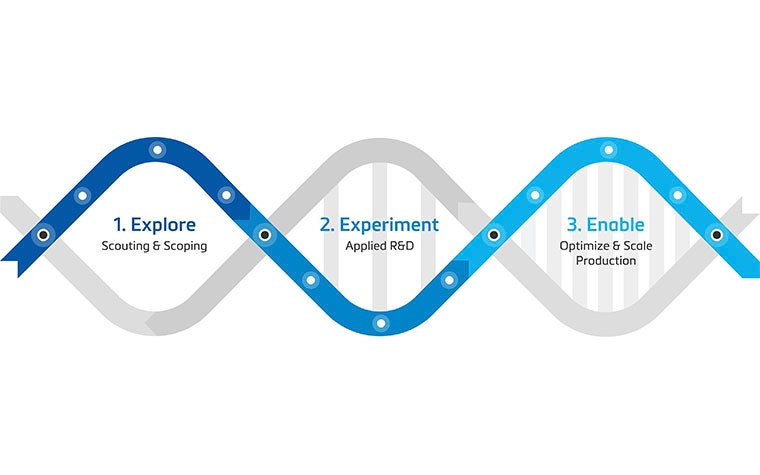

Just like with any other manufacturing technology, developing transformative products is a complex process. It always begins with identifying the right opportunity, going through applied research and development to validate the feasibility of the idea, and finally moving into certified production to materialize the initial business objectives. This is no different for additive manufacturing.

There’s no manual that teaches you how to integrate AM into your business. It can feel confusing, risky, and overwhelming because there are so many factors to consider and the next steps aren’t always straightforward.

In the past 30 years, we at Materialise have undergone this journey from uncertainty to fully automated certified manufacturing lines many times. Now, to help you navigate this journey, we’ve created a model that outlines the steps and key questions to consider during three main phases. We established this model by taking into account the unique challenges caused by the specificities of AM – for example:

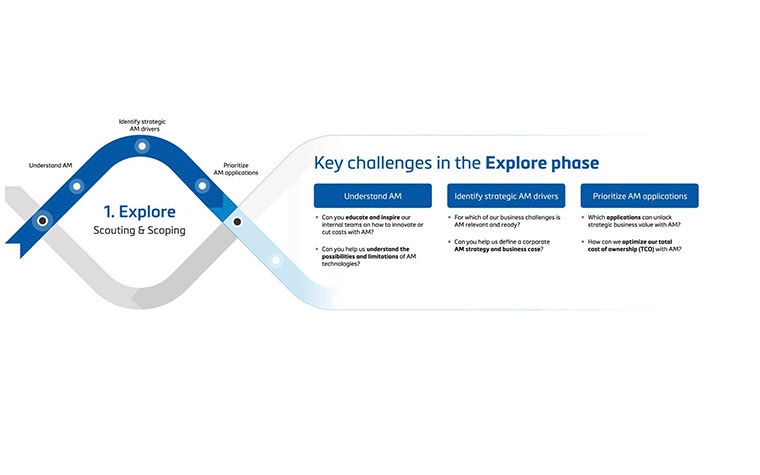

- If you are only beginning to explore 3D printing for your business, how do you determine if this technology can be the answer to your business’s strategic needs?

- If you are investing in R&D for your 3D-printed application, how do you experiment to determine which design variations will meet your product requirements for a given material or technology?

- If you have already reached a stage where you are involved in an experienced AM production and want to enable successful scaling, how do you identify the optimal build strategies to reduce scrap rates?

No matter which industry you come from or what you’re aiming to achieve, you’ll land in the Explore, Experiment, or Enable phase. Based on which phase you are in, Mindware can help you tackle the priority challenges and help you move closer to the next step in reaching your AM goals.

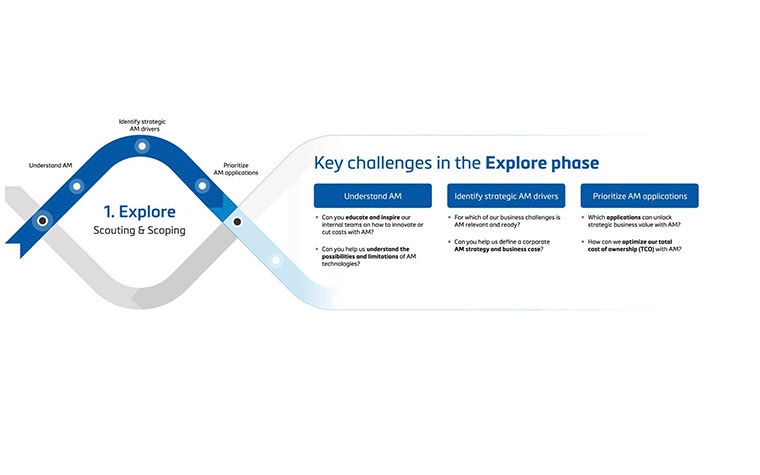

The first phase, and the one we’ll focus on with the following case, is Explore. Explore is for customers scouting and scoping the technology. This includes those who are looking to solve their business challenges with AM but need to determine where exactly 3D printing could add value and which application(s) to begin with.

This section of the model highlights the key challenges to address during the explore phase and addresses the questions our team can help answer.

Hyundai Lifeboats: Where was the leak in production?

Our project with Hyundai Lifeboats began in February 2018 with a request from the government of Ulsan, South Korea. The manufacturing industry in Ulsan is booming, and the government challenged us to meet with several companies to accelerate the development of 3D-printed applications.

This project was the epitome of Explore. Just as myself, the Director of Innovation at Materialise, and others from the Mindware team, had no experience or knowledge of producing lifeboats, the Hyundai team was unaware of the capabilities and limitations of 3D printing. So, the first step in this project was bringing our two worlds together to pinpoint a relevant business challenge for Hyundai Lifeboats that we believed could best be solved via additive manufacturing.

Easier said than done. We dove into an interactive workshop session in which we discovered each side’s perspectives, expectations, and blind spots. We first discussed how AM could increase the boat’s value — with enhanced speed, performance, functionality — but we were met with hesitancy from the Hyundai team.

When we asked what was on their minds, they quickly redirected the focus to the unit costs of the boat. They hoped that with 3D printing, they could simply press a button, grab a coffee, and print their boats in one go — thereby leapfrogging the current assembly and production process. Due to the large size of the boat and specific materials involved, we had to crush this AM dream, but at least we understood their main preoccupation: production efficiency.

As valuable as additive is, it’s not a quick fix. Like I mentioned before, it’s a whole journey. So, our team began with a tour of their production. Along the way, we looked at their process with a fresh perspective, asking business and technical questions during each step, and discovered why efficiency was one of their main concerns: the lifeboats were 100% handcrafted by the shopfloor workers. Up to 30% consisted of reworks and another 30% of scrap rates.

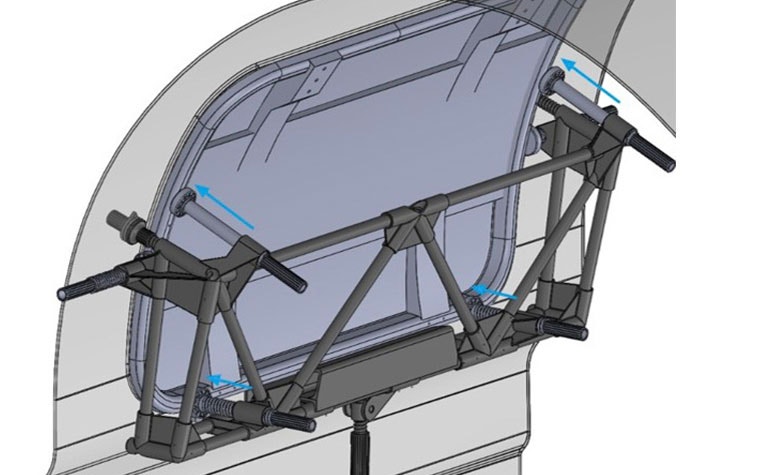

Upon reconvening after the tour, we mapped out every key step in their entire production process to identify their main areas of inefficiency and determined the step where we knew 3D printing could make the biggest impact: door assembly. Up until now, shopfloor workers had to lift each 20 kg door, align it manually, and assemble it to the rest of the boat. Clearly, this left room for error. During the splash test, if a leak was found because of errors from assembling the door, they had to go through the process all over again, disassembling then reassembling the door.

Their team had accepted that every boat would go through this process two to three times. And each rework was costing them valuable time and money. But we knew there had to be a better way.

3DP for smooth sailing

Using 3D printing to streamline alignment wasn’t a new concept for us. We already had experience developing 3D-printed guides to help surgeons perform more precise surgeries. We’ve helped automotive companies align letters on the back of cars with 3D-printed jigs.

After spending so much time carefully considering the problem and planning our strategy, we were ready to roll up our sleeves and develop a solution. And that’s when my favorite moment in our co-creation journey happened.

Our gears started turning, and with the team from Hyundai Lifeboats, we came together as one, despite our different languages, companies, and roles, to brainstorm the right solution. And then we started designing. And redesigning. And redesigning some more. Until, five whiteboards later, we all stepped back and knew that we had conceptualized the right solutions: three multifunctional jigs and fixtures to be used in the different steps of the production process. More specifically, a quality inspection jig and an alignment and positioning fixtures system.

After our three days with the Hyundai Lifeboats team were up, we returned to Belgium, where our engineers lifted the concept we created from the whiteboard and turned it into a digital design. We then created the physical proof of concept with our prototyping technologies.

Three weeks later, with the proof of concept in hand, we returned to Korea to measure and install the new systems with the Hyundai Lifeboats team. Our first results were quite promising. Operators no longer had to lift heavy doors into position. They could simply position the door on the system, and with the help of knobs and indicators, align the door correctly the first time.

And there we had it. By devoting ourselves to the Explore stage — asking questions, educating their team, and identifying which challenge we should tackle — we had a solution to their decade-long problem ready to test in just six weeks.

We combined all our unique experiences, be that in consulting, AM design, or lifeboat engineering, to successfully cover a leak in Hyundai’s lifeboat production line. We fully explored their processes, challenges, goals, and expectations to create a solution with additive manufacturing that would make a huge difference in their operations.

以下で共有する:

著者について

Kristel Van den Bergh