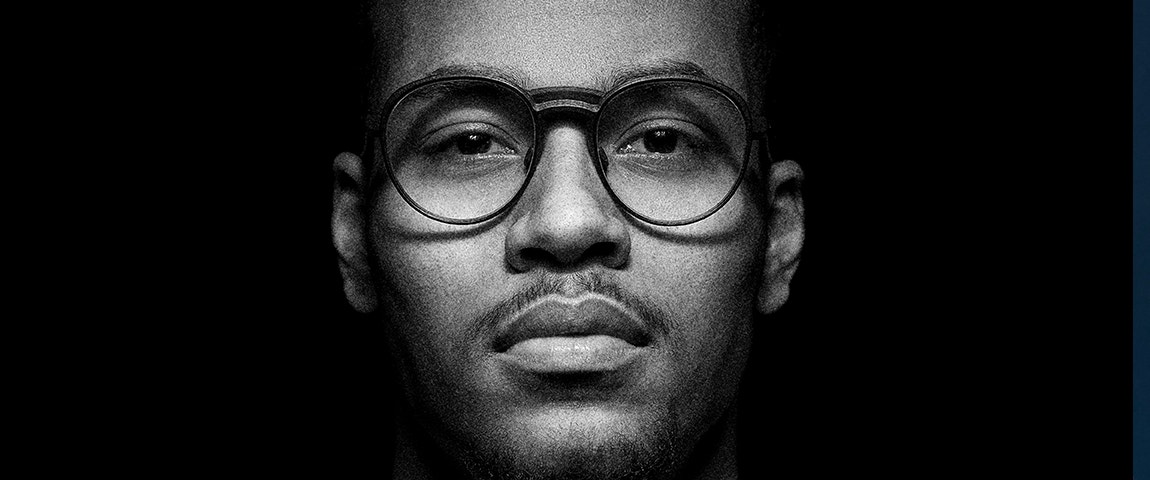

fmhofmann

Cosmos collection

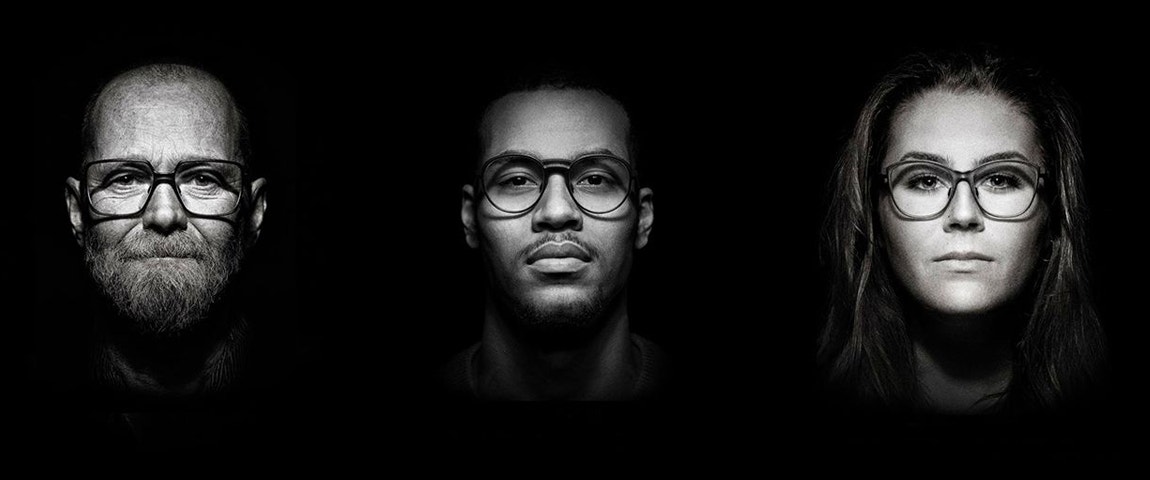

Inspired by the design freedom that 3D printing presents and armed with a creative concept unlike any other, leading designer Fabián Hofmann presented Materialise with a challenge: to partner with him in creating the industry’s first eyewear range with complex moving parts created entirely from additive technologies. With a 3D-printed titanium ‘VOID’ hinge, a lightweight open core frame design, and an entirely new surface finish, fmhofmann’s Cosmos eyewear range is unlike any the industry has seen before.

Bringing design DNA to life with 3D printing

The VOID hinge is startlingly simple, yet features a complex combination of different 3D-printed materials, a testament to the precise engineering required to realize the designs.

The hinge component and custom screws are all printed in titanium and allow the wearer to easily disconnect the PA frame and interchange components. There are five temple arms of different sizes the wearer can choose from, not to mention accessories such as visors, windbreakers, and shades that can be added to the eyewear frames.

fmhofmann’s signature style influenced the surface finish aesthetic on the 3D-printed frames to deliver the luxurious look and feel of leather. It’s a stunning example of how design and 3D printing can create something truly unique.

“Now that 3D printing has arrived in a broader market and printed consumer goods are finding an ever-growing audience, I strongly believe that we should not stop at this point of serial production but push the boundaries even further, striving to reach a new, advanced level of sophistication and product quality. ”

— Fábian Hofmann

Photo credits: ©2018 Benjamin Balsereit

以下で共有する: