EXPERT INSIGHT

Taking the Plunge: the When, How, and Where of Metal 3D Printing

3D printing offers huge design possibilities and cost-saving potential for manufacturers of metal parts. While the full industrialization of metal 3DP processes has only just begun, it is developing rapidly. And with product development cycles stretching across several years, parts designed right now may hit production at a time when metal 3D printing has matured to a mainstream manufacturing technique, one that might enable a better, more cost-effective, more innovative way of making that very product.

In short, now is the time to start considering 3D printing, during early product design phases. Here’s what to expect – and what to avoid – when making your first steps in metal 3D printing.

Current traditional industrial processes for the manufacturing of metal products have been refined over decades, if not centuries. Their requirements and limitations are deeply embedded in how we approach the design of, say, a cast part. We know the advantages and disadvantages, the economics and logistics of both casting and machining inside out. Consciously or not, we take all this into account during product design.

Metal 3D printing is no different in that it has its unique strengths, its own economics, its own rules. And because it’s only at the beginning of its evolution as an industrial process, knowledge of how to approach design and manufacturing in 3D printing is not yet widespread. Mistakes are easily made. That’s why it’s worth starting with some common mistakes to illustrate the difference in approach required, before looking at how to get it right.

Great expectations and rookie mistakes

The biggest mistake people currently make is to consider 3D printing too far down the product development roadmap. It’s usually considered when something didn’t work out as planned and a quick fix is needed. At this point, the assembly that the part sits in will have already been completely designed, and the main features of the part will be fixed.

On top of this, the expectation goes as far as believing that a part that has been designed specifically for machining can simply be printed instead. And it usually can. But it won’t be economical. In fact, it will be comparatively expensive, with little functional gain.

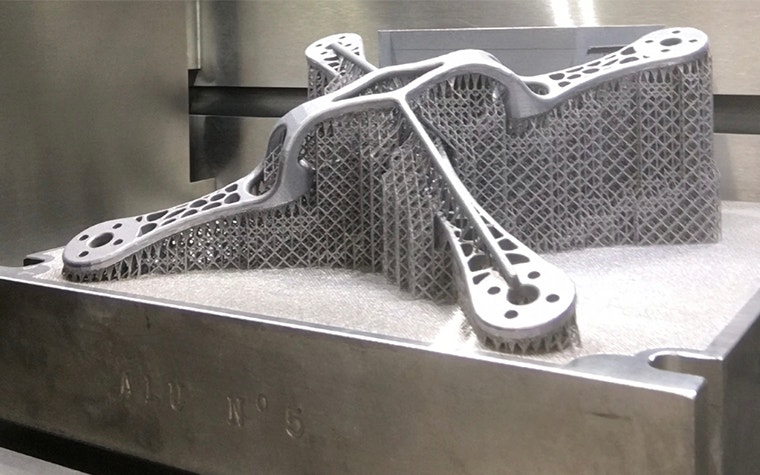

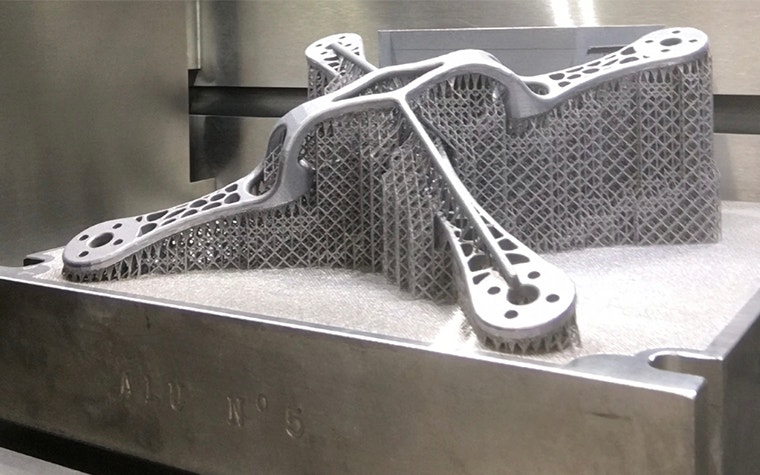

The advantages of metal 3D printing lie in the design freedom, in the possibility to completely rethink a part or assembly and do something entirely different – something that fulfils the desired function without the compromises that often have to be made with other manufacturing methods. If the part is already designed, these opportunities are locked out.

Cost and value

For many organizations who first dip their toe into metal 3D printing, the experience can – unfortunately and unnecessarily – be one of increased costs. But that is only the case if they failed to balance out cost with the value added. If designing the part differently can make it lighter or better, or combine several parts into one, then increased process cost pays off and can make the end part cheaper.

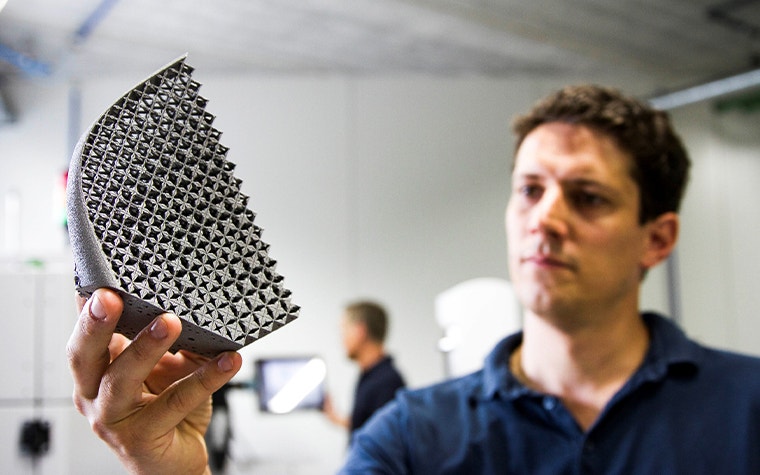

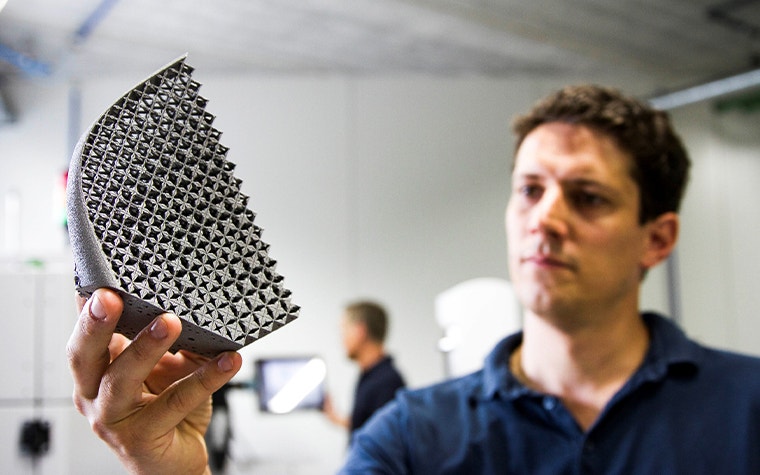

This can be particularly effective where expensive materials are involved. Not only does 3D printing enable incredibly lean, lightweight structures, it also uses only the material required for the part. There’s no milling down from an expensive block of titanium.

Getting the timing right

The biggest chunk of the eventual production cost of a part is set during the design process through design decisions that narrow down manufacturing options – with little room for later changes. But this is also where important aspects of the part’s value are decided. How much can it do, how many functions can it fulfill, how reliable will it be? This is where 3D printing can open new avenues, making timing crucial when it comes to using the technology successfully.

In 3D printing, complexity is free. This means complex structures to achieve a lightweight are suddenly an option. Functional integration of many parts into one becomes possible, because we don’t have to worry about how to create a mold or toolpath for an intricate, nested part.

Ultimately 3D printing comes into its own at the earliest stages of the design process, when neighboring parts and assemblies aren’t already fully designed, and when the production line for it isn’t already being planned.

Starting early means unlocking incredible value – and competitive advantage – as well as sufficient time to get the design and production infrastructure right and make sure the economics work. If done right, this can drastically improve tooling-up time as well as time to market.

Materials, volumes, infrastructure: planning ahead

The main current limitations to consider are available materials, production volumes and manufacturing infrastructure.

The readily available selection of alloys is still limited, but includes highly versatile types of titanium, aluminum, inconel and stainless steel, the mechanical properties of which can be modulated through design. For example, you may not need a lightweight material if you can easily create lightweight structures.

Production volumes and manufacturing infrastructure can also be tackled with time on your side. Initial, smaller runs or even bigger batches can easily be run through certified manufacturing services. The benefit here is that you don’t have to make the capital investment, and you also benefit from a multitude of additive manufacturing technologies. As your product and process matures, you will be able to make informed decisions about establishing your own 3D print infrastructure.

The same is true of the softer part of infrastructure – process knowledge, design capabilities, and software, as well as process and quality control. All this can be borrowed from a partner like Materialise.

Our mission is to drive Additive Manufacturing forward and make its added value available to industry. That means we are in it for the long haul – able to work out a sensible strategy for you that preserves and future-proofs your competitive advantage and allows you to make better products sooner. But whatever you decide to do, don’t miss the window for considering metal 3D printing in time for its breakthrough.

Condividi su:

Ti potrebbe piacere anche

Non lasciarti mai sfuggire una storia come questa. Ricevile una volta al mese nella tua posta in arrivo.