Materialise co-am

Quality & Process Control

Prove critical parts can be produced by AM

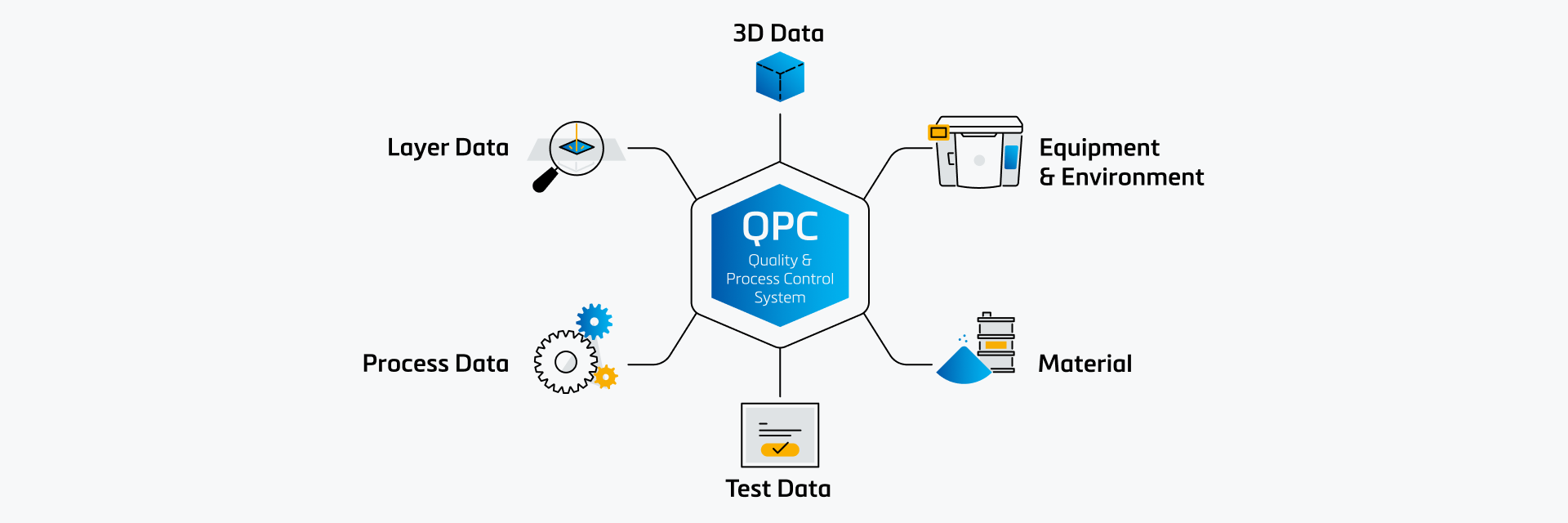

Transform additive manufacturing (AM) process monitoring and quality data into actionable insights using AI and IIoT connectivity in this secure, collaborative, and open software system. Build confidence in your 3D-printed end-use parts and demonstrate process stability throughout your AM workflow with QPC.

How to ensure repeatability with QPC

Overcome AM uncertainty with data

Leverage data-driven insights to ensure process acceptance and stability.

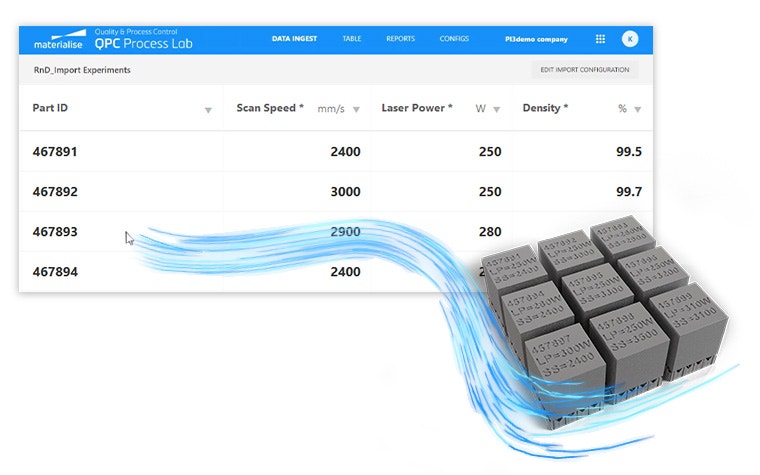

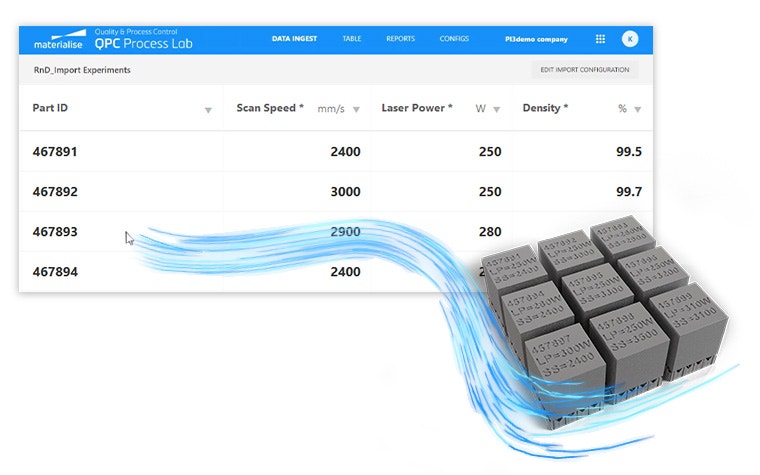

Improve R&D economics

Achieve material specifications in a cost-effective manner by optimizing parameter sets, including laser power, spot size, and scan speeds.

Get your process under control

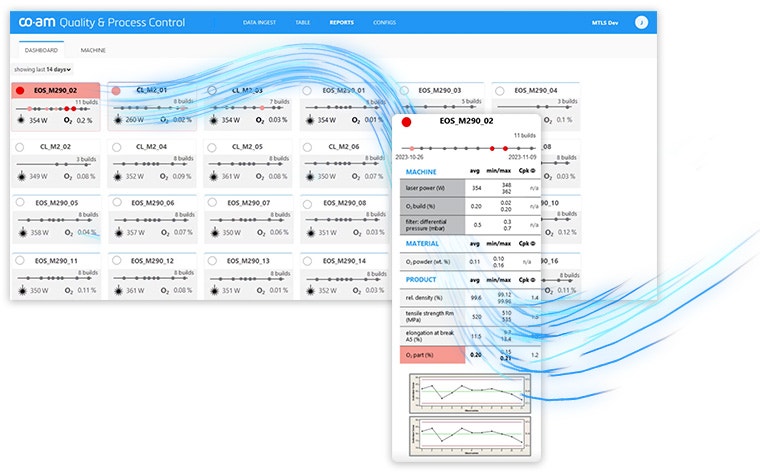

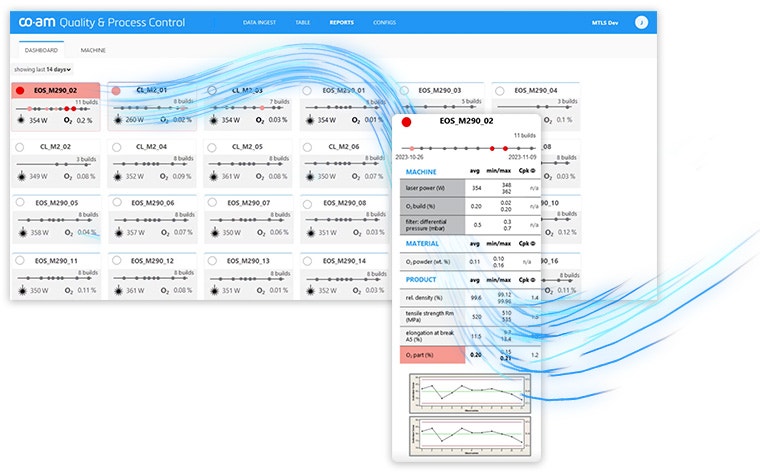

Ensure manufacturing repeatability by tracking and monitoring the accuracy of the production process across repeated experiments.

Identify defects and anomalies

Take advantage of AI-powered Layer Analysis for metal AM, quantify defects, and identify root causes based on correlated data across the process chain.

Instill confidence in AM

Research

Drive parameter development

Optimize process parameter sets to achieve material specifications and correlate material test lab results with AM process parameters and non-AM data in QPC. Plus, analyze data from third-party reports, machine sensors, and 2D/3D monitoring systems.

Validation

Demonstrate process control

Establish process stability for AM processes — and non-AM post-processing — through data-driven experiments. QPC recognizes unknown issues and unstable areas, allowing you to control processes with optimized parameter sets before production.

Production

Integrated QA and QC

Automatically flag anomalies, defects, and QA challenges via AI, and configure dashboards with this data for connected equipment. QPC also tracks material batches and machine maintenance digitally to help you execute statistical process control (SPC) and monitor key process variables (KPVs).

Root cause analysis

Investigate and solve issues

Leverage AI to identify anomalies and quantify defects while collaborating on one platform. Use QPC to correlate data from all sources for faster RCA and configure quality reports by filtering anomalies while emphasizing critical defects.

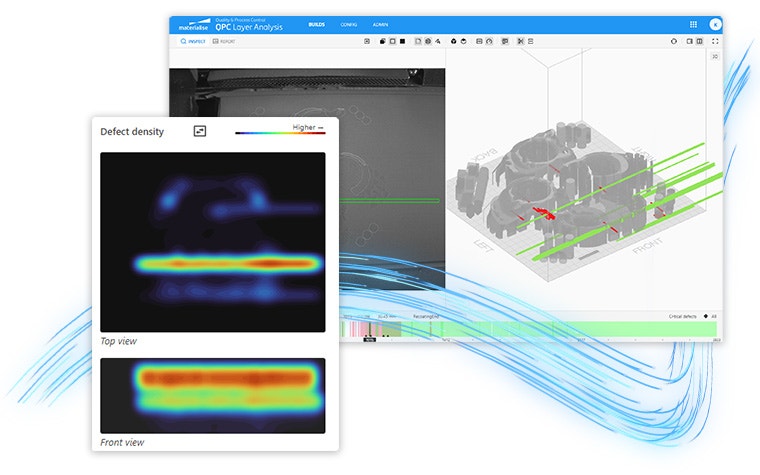

QPC Layer Analysis

Fail fast and improve AM ROI with Layer Analysis: a module that allows you to auto-detect and quantify defects in 2D layer data and map them to 3D models. Reduce manufacturing costs and identify scrap even earlier in the production chain.

Inspiration

Related products and services

Ottimizza e collega i flussi di lavoro AM all'area di produzione con sistemi aziendali, connettività delle macchine e soluzioni che migliorano la qualità della produzione.

Collegate le stampanti 3D e le apparecchiature ausiliarie al cloud per monitorare i dati dei sensori in tempo reale con avvisi e garantire la conformità dei parametri di produzione alle specifiche.