Point-of-Care 3D Printing

Start and scale a sustainable 3D printing lab at your hospital with confidence

Personalized patient care is increasingly becoming a reality, driven by technological advancements such as 3D printing and advanced visualization techniques. Having a dedicated in-house facility and support from Materialise engineers can cut days off the 3D printing process, support innovation initiatives, and result in lower overall costs incurred by the hospital.

The point-of-care 3D printing workflow

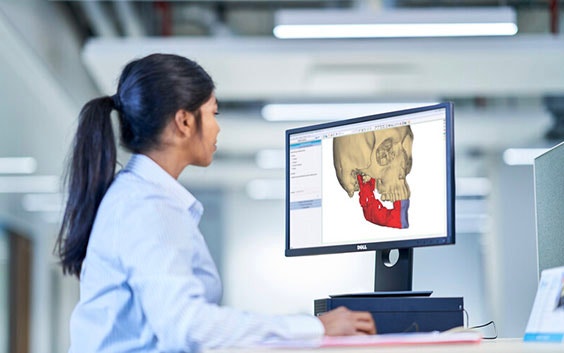

1. Image acquisition and segmentation

Combine automation with smart editing tools

3D medical image segmentation software

From scan to 3D model with ease

Maintain a comprehensive overview of your cases for up-to-the-minute updates in a quality-compliant system.

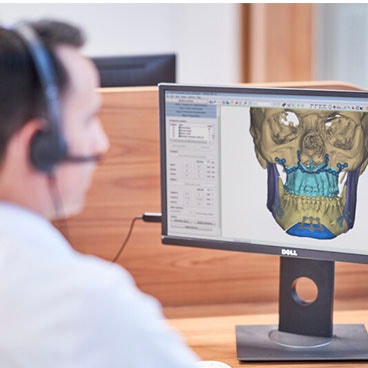

2. Virtual planning

Make critical decisions preoperatively to ensure better surgical outcomes

3D medical image segmentation software

Virtual planning for cranio-maxillofacial surgery

Maintain a comprehensive overview of your cases for up-to-the-minute updates in a quality-compliant system.

3. Design for 3D printing

Use the patient’s anatomy as the starting point for better accuracy

3D printing, design, and remeshing software

From scan to 3D model with ease

Maintain a comprehensive overview of your cases for up-to-the-minute updates in a quality-compliant system.

4. 3D printing

Print with hardware and software that’s fully certified for diagnostic applications

Set up a 3D lab validated for diagnostic use

Maintain a comprehensive overview of your cases for up-to-the-minute updates in a quality-compliant system.

5. Verification

Review and approve models with colleagues

Communication tool for engineers and physicians

Maintain a comprehensive overview of your cases for up-to-the-minute updates in a quality-compliant system.

6. Post-processing and quality assurance

Finalize models in accordance with your quality management system framework

Maintain a comprehensive overview of your cases for up-to-the-minute updates in a quality-compliant system.

Learn to integrate a system of your own with training modules by Materialise experts

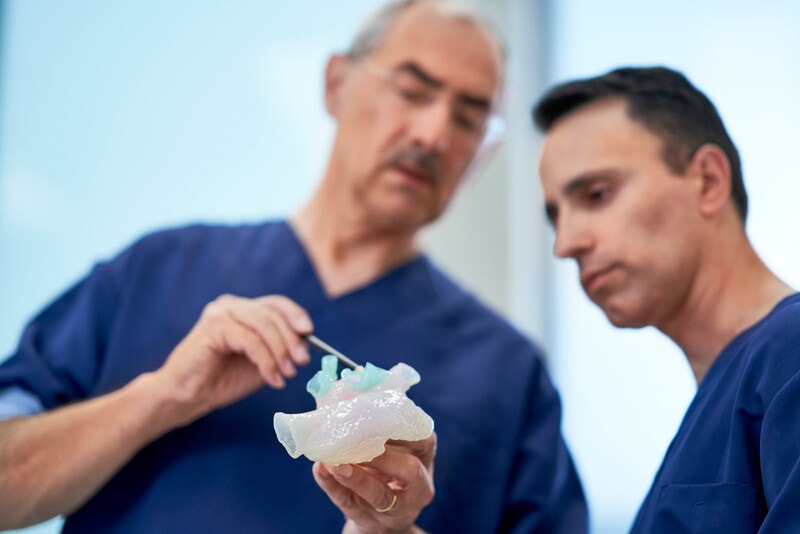

7. Final model

Your medical device is now ready to use

Benefits

A holistic platform tailored to your needs

Use an end-to-end solution consisting of printers, materials, and software that can be tailored to match your hospital’s needs as they change. Materialise is there to support you along the way, leveraging 30+ years of experience working with hospitals.

Quality and safety are the priority

Set up a successful quality management system and use materials, software, and hardware certified for diagnostic use to ensure safety. You can count on Materialise support to guide you with software, qualified workflows, and training.

Become part of a global community

Join our network of 450+ hospitals that have successfully implemented 3D printing and planning with us to gain access to training courses and events where you can discover best practices, the latest technology, and more.

Proven results that improve patient care

With 3D printing solutions, you can gain more insights and confidence before entering the OR, easily collaborate with multidisciplinary teams, reduce the length of hospital stays, and improve patient communication and consent.

What can you achieve with point-of-care 3D printing?

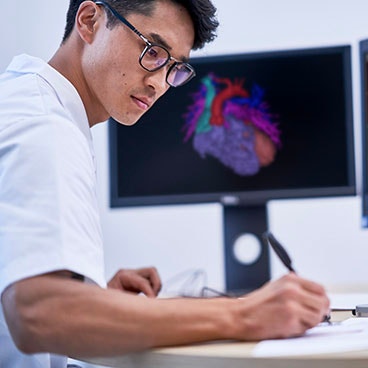

Surgical planning with anatomical models

Use anatomical models — virtual or 3D printed — for preoperative planning to determine the most effective treatment plan and reduce time and costs in the operating room.

Surgical guides

Create personalized surgical guides using sophisticated, industry-leading design tools to accurately execute your surgical plans in the OR.

Research and education

Teach the new generation of healthcare professionals with robust 3D printing tools and 3D models. Students can see, touch, and simulate interventions with realistic 3D-printed models.

Clinical evidence

In this study, they evaluated 260 patients and concluded that 3D-printed surgical guides and virtual surgical planning reduced the rate of radiographic nonunion and flap-related complications in FFF reconstruction for mandibular defects.

Short and long-term outcomes of three-dimensional printed surgical guides and virtual surgical planning versus conventional methods for fibula free flap reconstruction of the mandible: Decreased nonunion and complication rates (2021)

Seven studies using 3D-printed anatomical models in surgical care demonstrated a mean of 62 minutes saved ($3,720/case saved from reduced time), and 25 studies of 3D-printed surgical guides demonstrated a mean of 23 minutes time saved ($1,488/case saved from reduced time)

Medical 3D Printing Cost-Savings in Orthopedic and Maxillofacial Surgery: Cost Analysis of Operating Room Time Saved with 3D Printed Anatomic Models and Surgical Guides (2019)

According to one study from the Mayo Clinic, 88% of oncologic surgeons find models ‘very likely’ to improve the quality of care for patients.

3-Dimensional Printed Anatomical Models as Planning Aids in Complex Oncology Surgery (2016)

Due to shorter surgery times, 3D-printed models have demonstrated a reduction in intraoperative radiation exposure by as much as 50%.

Patient-Specific 3D Models Aid Planning for Triplane Proximal Femoral Osteotomy in Slipped Capital Femoral Epiphysis (2017)

3D-printed orbital models lead to a more accurate reconstruction and a time reduction during surgery.

Three-Dimensional Analysis of Isolated Orbital Floor Fractures Pre- and Post-Reconstruction with Standard Titanium Meshes and "Hybrid" Patient-Specific Implants (2020)

Inspiring content

L-100401-02