Technology

Vacuum Casting

Vacuum casting is a fast and cost-effective copying technique for producing high-quality plastic parts that are comparable to injection-molded components. Using two-component polyurethanes and silicone molds created from a 3D-printed master, this technique is especially suitable for fit and function testing, marketing purposes, or short series of end-use parts.

Why work with Materialise Manufacturing?

At Materialise, we can help you make a big impact with small series production. Our range of 26 carefully selected rubber-like, ABS-like, and PP-like polyurethanes provides an outstanding variety of properties. What's more, if you're looking for a specific finish, the teams at our dedicated vacuum casting center can match the exact finish you need for your parts.

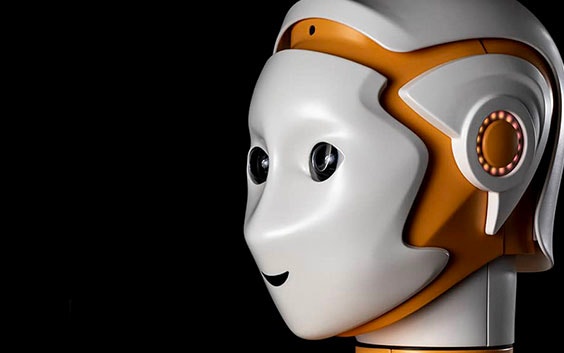

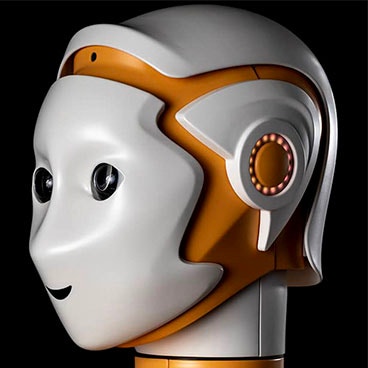

Discover applications of vacuum casting

Technical specifications

| Maximum build dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1,900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

| Standard accuracy | ±0.3% (with a lower limit on ±0.3 mm on dimensions smaller than 100 mm) |

| Minimum wall thickness | At least 0.75 mm to ensure the mold is filled properly; for best results, wall thickness of at least 1.5 mm is recommended |

| Surface structure | High-quality surface finish comparable to injection molding |

Materials

Choose from a broad selection of materials when you come to Materialise for your vacuum casting projects.

Rubber-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our rubber-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface quality and detail, resembling TPE, TPU, and silicone rubber

- Ideal for applications that need good shock absorption

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

ABS-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our ABS-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Flame-retardant, food-safe, and UV-stable materials available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

PE/PP-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our PE/PP-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Tough and lightweight with a wide range of finishes available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

Work with us: discover our products and services

Want to use vacuum casting in a future project? Discover the services that can help you do it.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Work with our experts to translate your business challenges into 3D printing opportunities and identify the applications that can help you meet your needs.

Train and learn

Get more from your next project with helpful resources dedicated to vacuum casting.