3D printed for speed and performance

Speed up, cost down

- Get new products to market with short lead times

- Decrease costs by reducing pulp usage and energy consumption and increasing speed and output

- Update designs and iterate quickly

Tools that perform

- Reliable tools that perform in harsh environments

- Remove the risk of corrosion or calcification

- Materials suitable for wet and dry process conditions

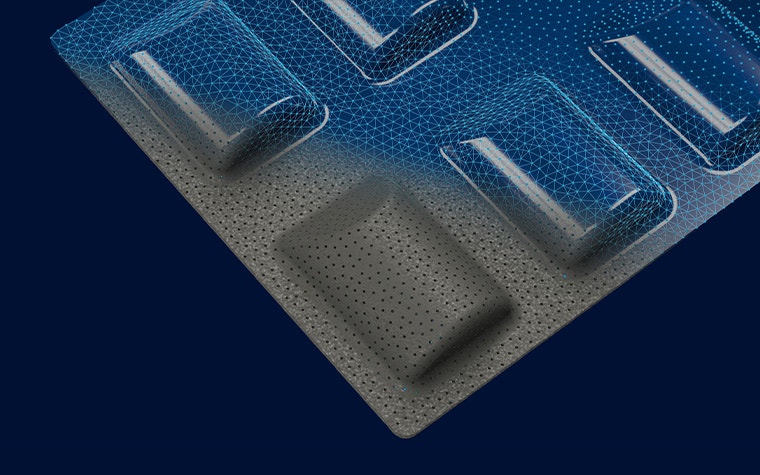

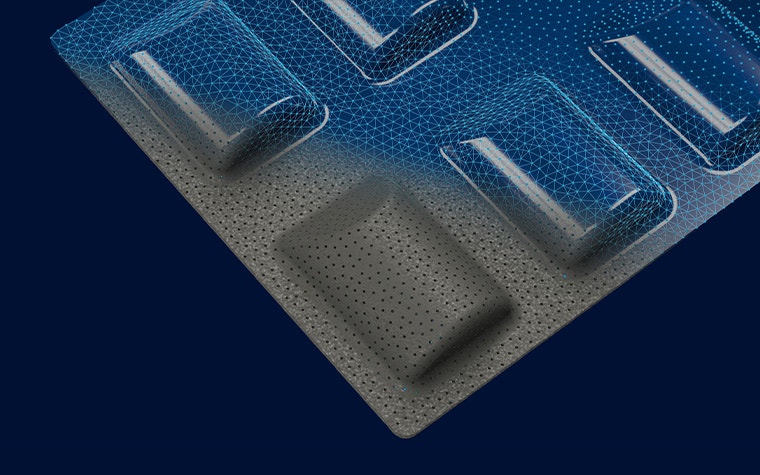

Functionality by design

- Design transfers, screens, or forms with complex geometries, precise perforations, and built-in channels

- Make tooling and end-use parts lighter

Expert support from idea to execution

Mold design and engineering

Create the ideal tool with our design knowledge and algorithms; integrate special features and ensure precise perforation and optimal heat conductivity.

Over 35 years of manufacturing experience

We produce thousands of 3D-printed parts every year. Our production capacity allows us to support you with prototyping, end-use production, and future upgrades quickly and on time.

The materials you need

Work with the ideal polymers and metals for molded fiber tooling. These materials combine high strength with low weight, corrosion and calcification resistance, and durability for high-quality tools that withstand corrosive slurries.

The right technology for the job

As a technology-neutral company, we’ll choose the right solution for your unique requirements and production goals. Our production facilities offer HP Multi Jet Fusion, selective laser sintering, and metal 3D printing.

Quality and certifications

Repeatable, traceable, high-quality production — all backed by a team that excels in bringing new designs to market.

Four steps to a successful partnership

Our design and production experts will work with you to evaluate your needs and requirements. You’ll receive a quote for the design and production of your new molding tool.

A session to gather all the technical input and requirements.

We’ll combine our 35+ years of additive manufacturing experience with CFD, FEA, and digital design assets to create the optimal design for your new tool. You’ll have the opportunity to review the design and request any changes before production begins.

Our 3D printing experts will produce your tool while following our detailed quality control process. After a final technical intake, we'll send your parts directly to you.

Excellence through experience

Materialise has been the trusted name in additive manufacturing for over 35 years. We’ve produced hundreds of thousands of end-use parts, tools, and equipment for industries like aerospace, automotive, and medtech.