Art and Design

Explore new opportunities with 3D printing

With 3D printing, you don’t have to limit your creativity. Design without constraints. 3D printing’s freedom of design allows you to create shapes, structures, and concepts that are impossible with other manufacturing techniques. Realize your ideas with speed, push the limits of creation, and try out a new toolkit for art and design.

Why choose 3D printing?

Bring your creative vision to life

3D printing allows you to construct designs with intricate shapes and geometries. You will no longer be constrained by the medium or production method.

Recreate history

Producing a replica of an artifact by hand can be challenging, time-consuming, and result in inaccuracies. With 3D printing, digital scan data of an artifact can be easily converted into a 3D printing file, saving time and maintaining fine details.

Gain complete control

Quickly and easily iterate with digital designs and 3D-printed prototypes. Plus, 3D printing doesn’t require expensive molds or raw materials, making one-off projects achievable and cost effective.

Why choose Materialise Manufacturing?

Wide range of materials and finishes

With eight technologies and dozens of materials and finishes to choose from, you have access to a diverse range to ensure your design looks and performs exactly as intended.

Dedicated project management

Our project management team has years of experience looking after the production of parts, offering advice, and recommending the perfect 3D printing process for your vision.

Design and engineering guidance

Our Design & Engineering team works with you to help you create your pieces, ensure parts will print successfully, and confirm post-production assembly runs smoothly.

Ideal materials for art and design

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

Polypropylene (PP)

Technology

Selective laser sintering

Description

A tough, fatigue-resistant, and lightweight material, polypropylene (PP) is ideal for functional prototypes of snap-fit assemblies or living hinges in automotive components, packaging, and consumer goods.

Key characteristics

- Tough yet flexible material printed without a support structure

- Very high elongation at break (> 500%)

- Lightweight and fatigue resistant

- Max part dimensions: 480 x 480 x 430 mm

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

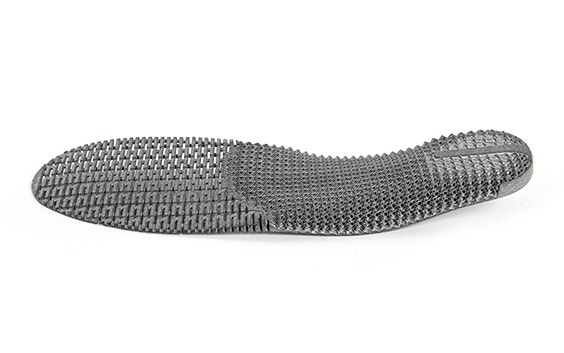

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

Poly1500

Technology

Stereolithography

Description

Poly1500 is a durable, resilient material that offers high surface quality and dimensional accuracy. With properties similar to polypropylene, it is ideal for functional prototypes.

Key characteristics

- Similar properties to polypropylene

- Good durability, impact resistance, and heat resistance

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

ProtoGen White

Technology

Stereolithography

Description

ProtoGen White's resilience, surface quality, and thermal properties make it suitable for general-purpose applications such as RTV molding patterns, highly detailed parts, and durable concept models.

Key characteristics

- Similar properties to ABS

- Resilient material with good surface quality

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

TuskXC2700T

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700T is a strong material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes and high-end finished models. Transparent finishes possible.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Great surface quality, with transparent finishes possible

- Among the largest printing volumes of stereolithography materials

- Fast Lane service available for online orders of TuskXC2700T – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 2,000 x 700 x 788 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

ABS

Technology

Fused deposition modeling

Description

Known for its toughness, durability, and affordability, ABS is one of the most widely used industrial thermoplastics. It is suitable for prototyping, tooling, and end-use parts.

Key characteristics

- Tough, durable material

- High impact strength

- Up to 80% of the strength of injection-molded ABS

- Fast Lane service available for online orders of ABS White/Black – Normal finish

- Max part dimensions: 300 x 300 x 300 mm

- Max part dimensions (Fast Lane orders): 250 x 250 x 300 mm

Aluminum (AlSi₁₀Mg)

Technology

Metal 3D printing

Description

The strength, thermal properties, low weight, and flexible post-processing of this aluminum alloy, AlSi₁₀Mg, make it ideal for prototyping and manufacturing in industries such as automotive and aerospace.

Key characteristics

- Offers the largest printing volume of all metal 3D printing materials

- Lightweight, with good strength-to-weight ratio

- High thermal and electrical conductivity

- Suitable for post-machining

- Max part dimensions: 500 x 280 x 345 mm

Typical uses of 3D printing in art and design

Art installations

Don’t limit your creativity — 3D printing’s freedom of design allows for anything from large installations and structures to small, detailed pieces.

Fashion and costume design

Create unique garments that push the boundaries of what’s possible. 3D printing’s freedom of design, materials, and finishes give you the tools to carve a new path in fashion.

Props and set pieces

Print pieces as needed with speed and ease. Leverage design freedom to create intricate pieces that would be impossible to create by hand or with traditional methods.

© Matt Kenneda/Marvel Studios 2018 - Costume Design Ruth Carter

Sculptures and models

Test concepts during the development phase with physical models that can guide you while creating the final design. Create a unique design with 3D printing to fully unleash your creativity.

Replicas of historical artifacts

Accurately reproduce ancient models, historical figures, or artifacts. 3D printing covers everything from large-scale models to fine, intricate details.

Our products and services for art and design

Ready to start your project with us? Discover our solutions, ideal for your industry.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Generate lattices, create textures for an aesthetic finish, and achieve post-topology optimization.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Inspiration

Other industries we work in

Navigate the future of aerospace with shorter lead times, more affordable small series production, and the unrivaled design freedom that additive manufacturing can offer.

From quick, performant prototypes and visual models to small series manufacturing and automotive tooling, tick every box by bringing 3D printing into existing or new production workflows.

Enter a new era of more sustainable, on-demand manufacturing where creativity and innovation have no boundaries and where quick time-to-market, and zero stock-risk, boost business agility.