Build, customize, and optimize

Differentiate yourself in the market

Provide customers with a better 3D printing experience through application-specific build processors customized to their needs. Improve process control, minimize pre-processing times, and increase productivity and quality with our advanced build processors.

Innovate without revealing your IP

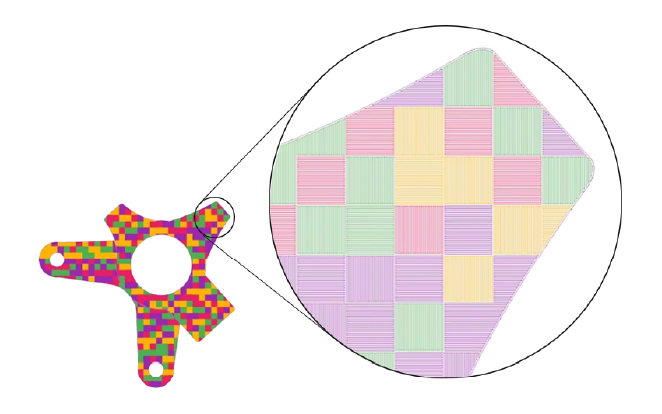

Leverage over three decades of AM experience and expertise. Empower yourself and easily integrate your existing technologies into the Build Processor Software Development Kit (BP SDK) to develop creative hatching, scanning, and supportless strategies.

Gain control of your software releases

Build at your own speed with the Customer Make program. Give your developers advanced tools and extensive documentation to support customer demand based on their application needs.

Connect CAM software

Streamline data and build preparation with Magics 3D Print Suite and generate job files using build processors designed for your 3D printers. Simplify complex processes and ensure that preparing job files for production becomes effortless for customers.

Accelerate your time-to-market

Leverage the standard NxG BPs designed for different 3D printing technologies, and let us configure these BPs for you with our Materialise Make program. Launch your 3D printers quicker for your go-to-market strategy.

Unlock AM applications

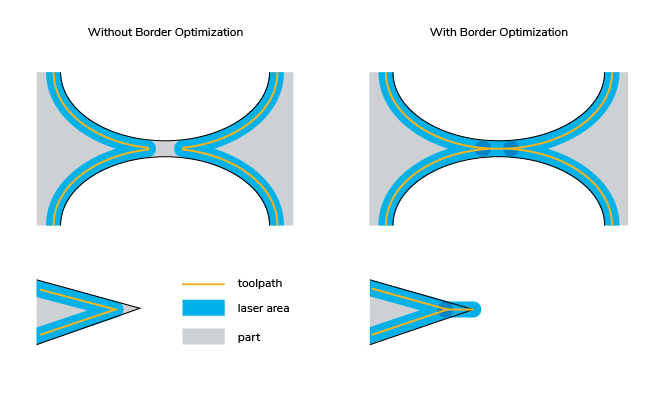

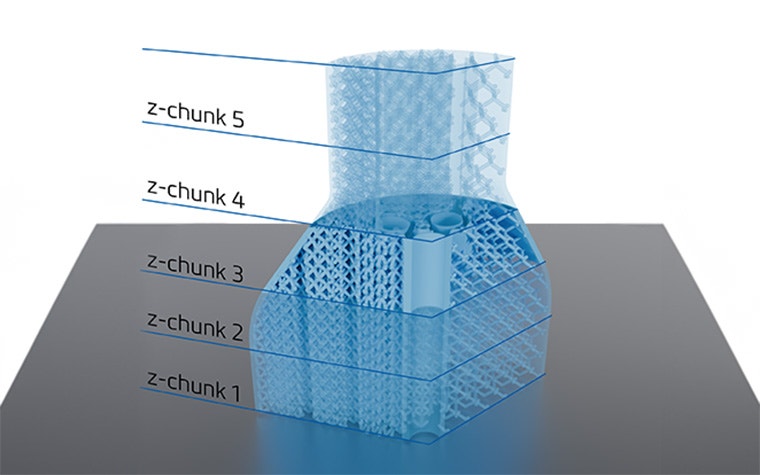

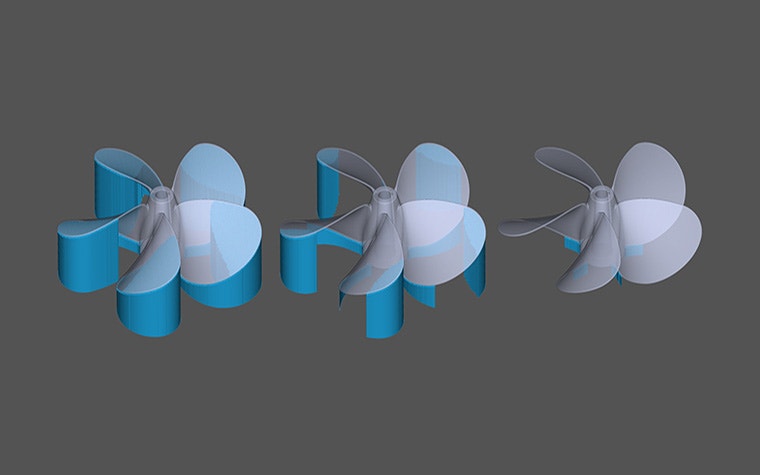

Support customers in achieving their goals by helping them develop complex features like thin walls and processing large implicit files. Overcome challenging obstacles, reduce scrap rates, and print first time right by using our expertise in AM and advanced BP software.

Solutions to enable your competitive edge

NxG BP

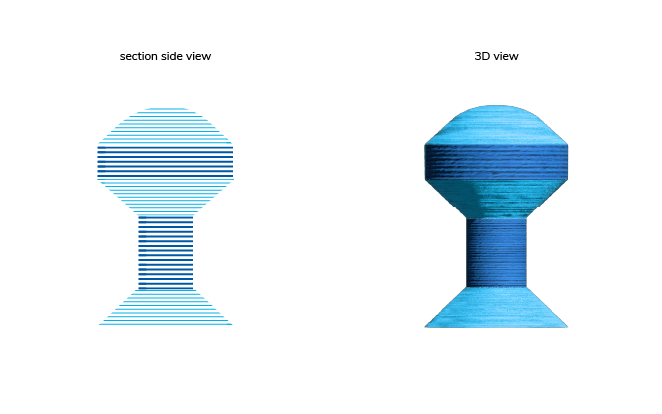

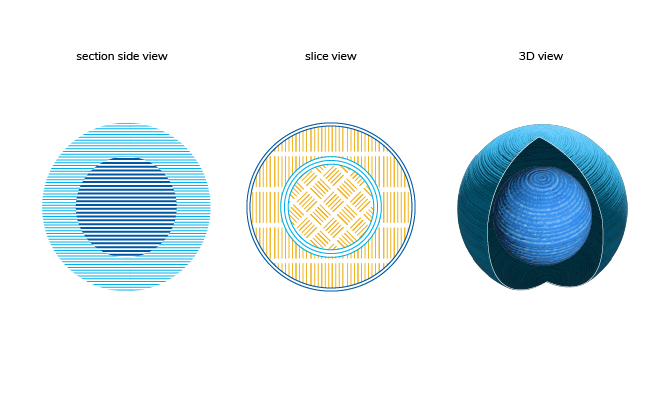

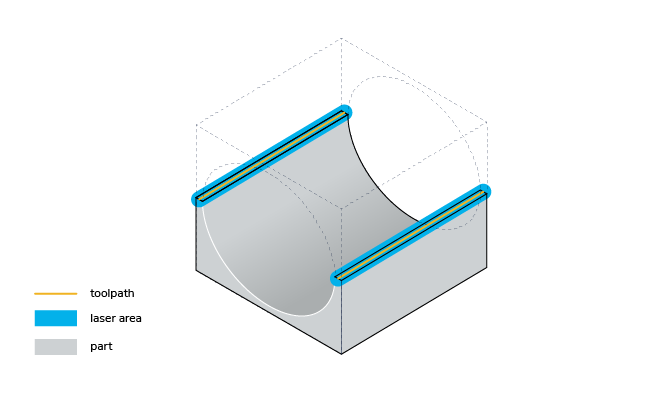

Leverage off-the-shelf build processor algorithms designed for toolpath-based technologies (such as LPBF, SLA, SLS, and EBM) and image-based technologies (such as DLP, BJ, and MJ). Plus, easily customize these algorithms by adjusting and integrating them with your IP.

BP SDK

Push the limits of your AM technologies by leveraging proven AM build file generation algorithms to build custom BPs with the BP SDK. It allows you to offer proven technologies as a starting point for your team or enables customers to optimize their 3D printer even further.

AM workflow integration

Our NxG BPs empower you to scale your build processor development with customizable BPs that can be built at speed, enabling shorter and cheaper software development cycles. Furthermore, they work with Magics and within the Materialise CO-AM Software Platform to provide you and your customers with a complete AM software ecosystem. Alternatively, NxG BPs also operate independently to support your AM workflow as you see fit.

Capabilities of the NxG BP

Choose your build processor development path

Next-Gen Build Processors are built upon the foundation of BP SDK, a tool that provides the primary building blocks to create personalized BPs that can improve the productivity of your 3D printers. Inquire about our Materialise Make and Customer Make customization programs to explore which development path suits you.

Materialise Makes | We make your BP for you

Take advantage of 30+ years of AM experience embedded within our NxG BP off-the-shelf solution. Easily configure existing BP parameter settings to your needs.

Customer Makes | Customize your BP

Push the limits of your 3D printing technologies by customizing BP algorithms with BP SDK. Additionally, BPs can even be integrated with your IP and existing software.

Frequently asked questions

Materialise Next-Generation Build Processors

Configure a standard Build Processor with our help, or develop and customize your own using the Build Processor Software Development Kit.

Unleash additive manufacturing's full potential with software consultancy services tailored to your journey.

Discover our library to learn about Build Processors for your machines.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Connect and streamline your AM workflows to the production floor with business systems, machine connectivity, and solutions that improve quality output and ROI.