EXPERT INSIGHT

30 Years of Materialise: Revolutionizing Healthcare Engineering to Enable Better and More Predictable Patient Outcomes

With the help of medical image-based population analysis software and services, anatomical engineers can now quickly test new devices on hundreds of virtual patients as well as create representative physical test models. This is leaps and bounds over traditional methods. It is an alternative to testing on cadavers, which can only test one device on one specific person’s anatomy. Now, testing can help accelerate innovation, improve device performance, and prove their benefits.

This innovation, known as virtual patients, slashes the time needed to bring a product to the market by reducing the number of design iterations. And yet, it is just one of the tools in hand to accelerate the research and design process. By increasing anatomical understanding, the medical field is on the path to have safer and more predictable outcomes.

As Materialise is celebrating its 30th anniversary this year, we are taking a look back at the most meaningful innovations over the company’s history with a series of blog posts. To begin, we’re reflecting on some of our medical innovations as examples of our commitment to a better and healthier world.

A natural pivot to medical

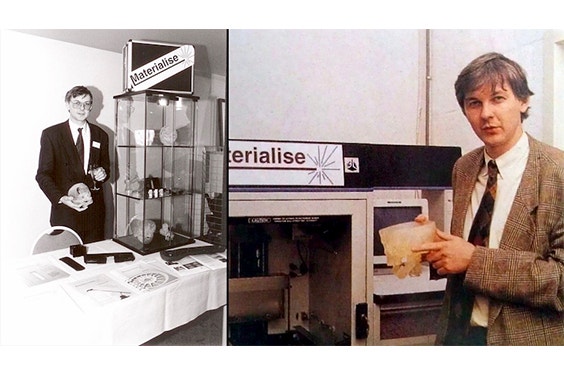

In 1990, Materialise began as a service bureau to provide 3D-printed parts to companies. The initial idea was that with 3D printing, it would be possible to have faster design iterations during the prototyping phase. But soon Materialise’s mission went further and extended into the medical field: Materialise CEO and Founder Fried Vancraen realized that the 3D files they used to print various objects had unique similarities to medical scans.

In order to create a 3D print, software breaks down a design file into thin slices to instruct the 3D printer on what to do at each layer. As Fried looked at how 3D printing files were essentially stacks of very thin slices, he realized that these files are very similar to CT scans, which are images taken of patients that are also split into very thin slices.

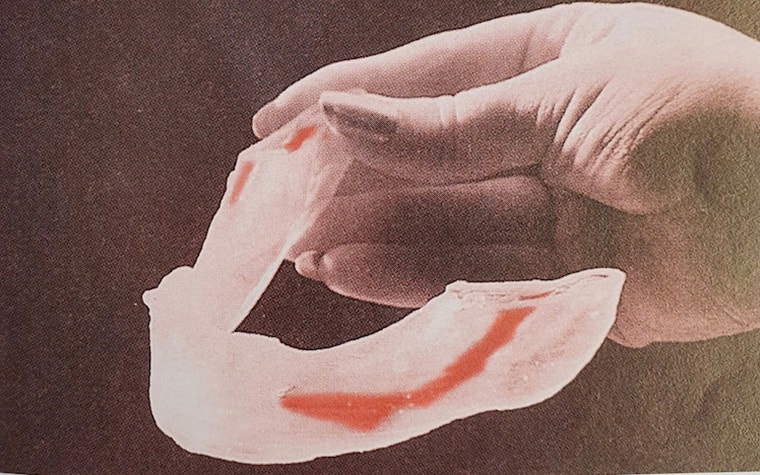

This lightbulb moment led to the first version of Materialise Mimics just two short years after the company was founded. With this software that connects medical data to 3D printers, Materialise could create anatomical models based on an individual patient’s unique anatomy. Fried wanted clinicians to have a physical print of their patients’ anatomies, so they would better understand complex cases. Additionally, through 3D printing, creating one-off personalized devices such as implants and guides for surgeries became an achievable goal. The first cases using anatomical models were for patients with brain tumors and helped clinicians see where they could make critical, precise cuts without adversely affecting the surrounding precious parts of the brain.

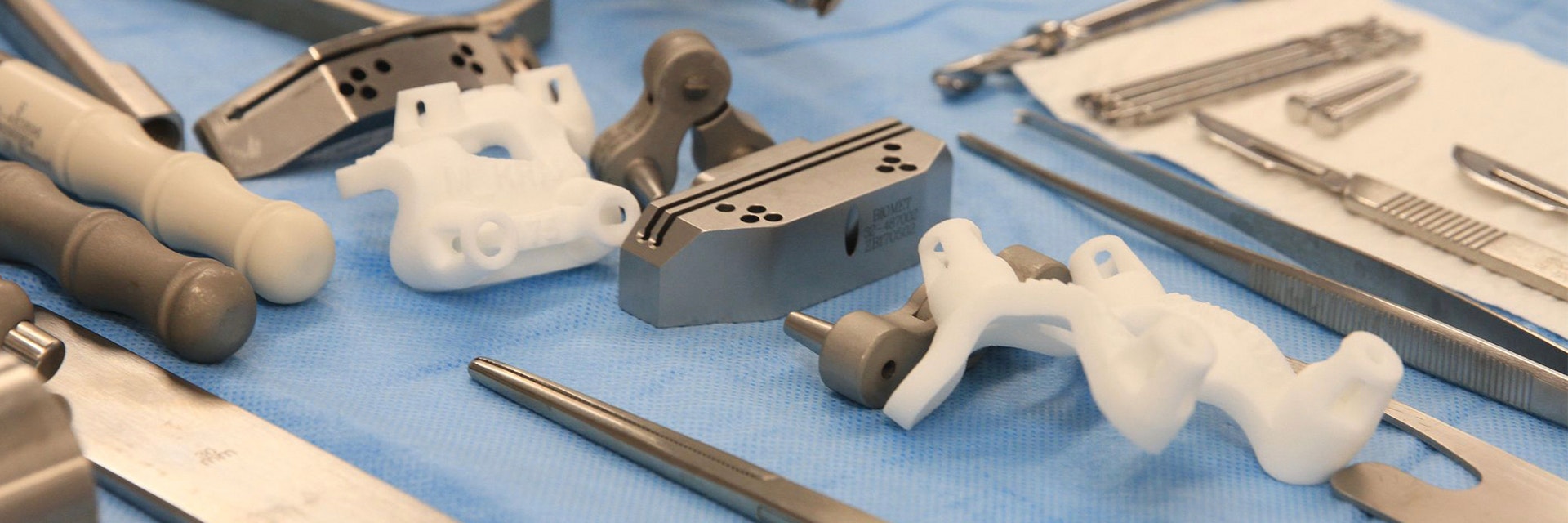

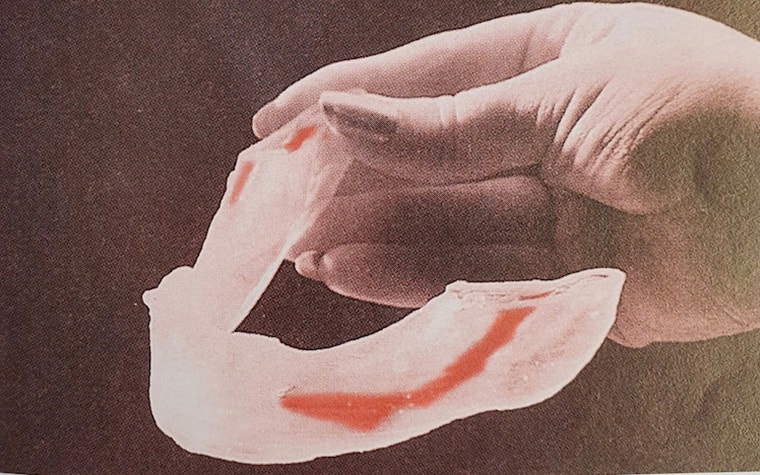

After anatomical models, Materialise continued with 3D-printed guides that could be used during surgery, allowing surgeons to accurately cut and drill for implants. The initial focus on dental enabled clinicians to be able to virtually 3D plan a procedure and print a customized guide to translate this planning accurately to their patient.

Co-creation and partnerships driving innovation

The birth of Materialise Mimics paved the way to uncharted possibilities. Examples of innovative solutions include anatomical models, surgical dental guides, cranio-maxillofacial guides, and personalized implants, which all contributed to more confidence for clinicians and better outcomes for patients. From the start, Fried believed that co-creation — minds from different companies and fields working together with our software, technology, experience, and expertise — was the key to innovation. Additionally, Mimics was made available to other companies so they could further their own research and development. With this holistic view of the business ecosystem that has continued today, co-creation and partnerships remain pillars of our foundation.

This foundation has helped many of our partners scale from research and development (R&D) to high-volume clinical operations. Some companies use our software to design products to print and produce in-house, while other companies need a turnkey solution that covers the complete product lifecycle, such as our personalized, cranio-maxillofacial (CMF) implants being offered through DePuy Synthes TRUMATCH® CMF Solutions.

“At Materialise, we strive to make medical 3D printing accessible to every researcher, engineer, and clinician, through an open platform of software and services that help customize patient treatment. ”

— Fried Vancrean, CEO and Founder

Present-day evolution

Today, there are many paths of innovation stemming from advances in medical engineering that include 3D planning, virtual patients, point-of-care 3D printing, AI to improve pre-operative planning, and beyond.

In particular, virtual patients have come a long way from just an idea to becoming standard practice when it comes to the development process of orthopaedic implants. At its core, virtual patients are computer models of patients that help predict the response of patients to the treatment.

In the example of Exprt® Revision Hip, DJO Surgical was able to quickly improve the fit of the implant with a variety of different bone sizes. This was all while saving time and money through a faster iterative process with the reliability of the verification and validation process. Having this tool also helped surgeons and engineers communicate more easily through data that they could both understand. With so many benefits, this advance in medical engineering has easily become a standard for DJO Surgical.

Materialise’s expertise in research & development and design & engineering came together for today’s global pandemic when we developed and manufactured a 3D-printed NIP connector that holds together standard medical equipment — a mask, an air filter, and a PEEP valve. As patients are facing severe respiratory issues, the UZ Leuven hospital is leading a clinical trial for a solution that bridges the gap between a simple oxygen mask and intubation. Our medical engineers worked together with doctors to create this non-invasive solution using our know-how in medical device design, regulatory processes, and certified medical manufacturing. Guided by our three decades of engineering for 3D printing, we were quickly able to face the pandemic with scalable and impactful solutions.

New shared horizons to come

We see a continuation in our mission of making personalized care more sustainable through process automation and better integration in the digital healthcare ecosystem. As Materialise makes strides in technology, we look forward to continuing strong collaborations with others to break new ground in the medical field, bringing predictability and improving patient care while mitigating risk. After 30 years of developing meaningful applications across the medical field, we are proud to look back and see how our technology has helped impact so many lives.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.