EXPERT INSIGHT

How to Get Started with 3D Printing for Maximum Business Impact

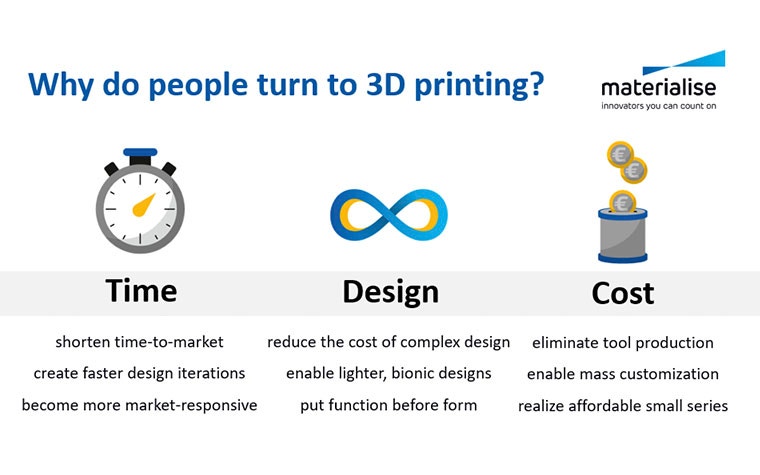

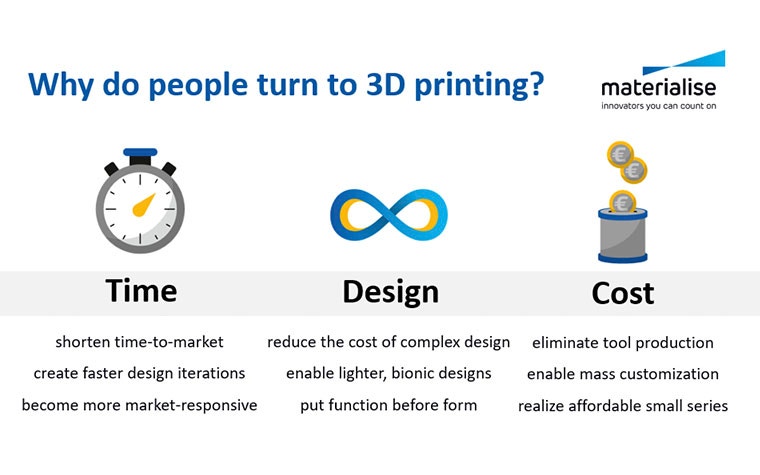

There is no shortage of resources to learn about 3D printing. But for those of you just becoming acquainted with the technology, it can be overwhelming to understand what exactly it could do for you. One of the very reasons why people turn to 3D printing is because it is so versatile. To avoid feeling overwhelmed by these numerous opportunities, beginners turn to the know-how and advice of those with experience in the industry.

This is why we are sharing an outline for your own 3D printing journey with this breakdown of the technology’s main advantages.

Freedom of design

3D printing has led many companies to rethink and shift their approach to product design. With 3D printing, you get the ultimate freedom of design capability. Instead of designing parts for manufacturability, you can instead almost exclusively focus on designing for function. In product design, this means you can improve part performance by consolidating parts and creating complex shapes.

For instance, by using lightweight design and combining four parts into one by using 3D printing’s freedom of design, Philips is now saving around €89,000 a year. This was the result of a co-creation process between Philips and Materialise, where the two companies combined their expertise to rethink the entire production line. They could then design parts based solely on the requirements in the ideal factory process, leading to a "reinvented" lamp holder bracket, which was previously prone to part failure, and redesign a suction gripper.

Shorter supply chains

Another benefit of designing without the uncertainty of manufacturability is that you don’t need to worry about the tooling costs that come with other technologies. This brings about shorter supply chains as there are fewer steps between design and the final product. Shorter supply chains also mean that you can reduce the amount of stock stored in a physical warehouse and use a digital warehouse to deliver parts more rapidly. And while 3D design files can be sent from anywhere in the world, printing parts locally, thanks to access to this digital warehouse, can significantly reduce transportation costs.

Take Volvo Car Gent, for example. Almost half of Volvo’s annual vehicle production takes place at this location. They recognized the benefits that 3D-printed parts could add to their production line and turned to Materialise for quick, local manufacturing that matches their own fast-paced ecosystem. Working alongside Materialise’s design experts, this project resulted in a gluing jig that weighs 64% less, can be delivered in only two weeks, and is nearly half the price of the previous jig.

Fast time-to-market

On-demand manufacturing leads to greater agility by enabling brands to be market responsive without generating unsustainable stock risk. Virtual inventories and tool-less manufacturing also open the potential for drastically shorter lead times, reducing manufacturing downtime significantly. These benefits lend themselves well to the replacement parts industry in which keeping a costly physical inventory of spare parts becomes a thing of the past.

Koiwai, a Japanese metal part manufacturer, experienced 3D printing’s fast time-to-market capabilities firsthand when they made the change from wooden molds to sand molds manufactured via 3D printing. Thanks to this fundamental change and collaboration with Materialise and advanced 3D printing software, Koiwai reduced lead time by a whopping 90%. Their casting time was reduced from ten days down to only one day.

Revolutionary innovation

Manufacturing with a digital warehouse can also lead to industry-changing ideas. For example, HOYA disrupted the entire eyewear industry by offering tailor-made glasses. A scan of a customer’s face allows them to design glasses for that individual, meaning they can offer glasses that have a fit unseen elsewhere on the market. Since each 3D print is made-to-order, there is no need for excess stock, an issue common in their industry. Plus, they did not need to invest in expensive machines. By partnering with Materialise, they have access to the largest additive manufacturing factory in Europe and many other machine parks around the world.

“AM allows us to react better to changing market needs. ”

— Félix España, Global New Media Manager, HOYA Vision Care

It’s not ‘all or nothing’

The future of manufacturing includes integrating 3D printing possibilities, principles, and solutions into your understanding of how we make things. But it does not have to be seen as an "all or nothing" approach — it can be adopted into the traditional value chain at many different levels to yield meaningful applications, add flexibility to the production process, and maximize cost savings.

“Today, we use 3D printing at every stage of the process: for visual prototypes, proofs of concept, functional prototypes, and production line tools,” says Vivien Cheng, Head of Product Development at Samsonite Europe. Even though Samsonite requires a high volume of 3D-printed parts on a weekly basis, the company has made a strategic decision to rely on external suppliers like Materialise rather than setting up its own 3D printing production facility — a decision driven by cost-benefit, flexibility, continued access to leading-edge technology and fruitful creative partnerships with 3DP domain experts.

“3D printing helps us get the right design on the market fast — while meeting the high standards our customers expect from the brand.”

— Vivien Cheng, Head of Product Development at Samsonite Europe

In times when missing the boat can bring about the decline of industry giants, 3D printing can unlock unseen potential and be impactful across your value chain. And a partnership with a technology-neutral company like Materialise means that you can see what makes the most sense in terms of design, process, and whether to set up in-house or use an external supplier.

For those of you just getting started, we recommend learning more by downloading our whitepaper below. There you will get more details on how 3D printing fits into the greater manufacturing landscape and Industry 4.0 and what to consider when determining if the technology can help you overcome your biggest challenges.

Or, if you’re ready to dive in, get in touch to see what 3D printing could mean for you.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.