EXPERT INSIGHT

Why 3D Printing Has Tremendous Potential in Radiotherapy

3D printing, also known as additive manufacturing, is transforming the field of radiotherapy by supporting more accurate and better patient treatments, improved applicators, and more. Below, we will cover different applications, challenges, and the potential of what it can do in the future.

Different radiotherapy applications

Here are a few of the key benefits of 3D printing for four different radiotherapy applications:

Customized immobilization devices

With 3D printing custom immobilization devices can be created to precisely position the patient for treatment. Designed and printed to fit the patient's unique anatomy, these devices improve treatment accuracy and reduce the risk of side effects.

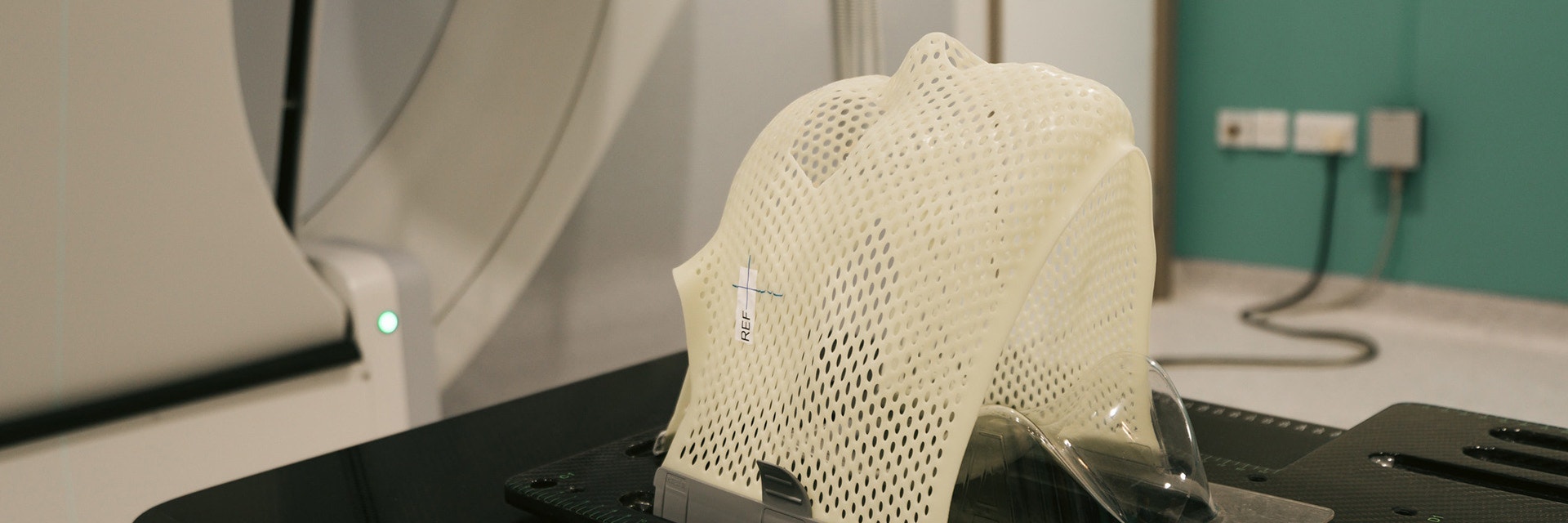

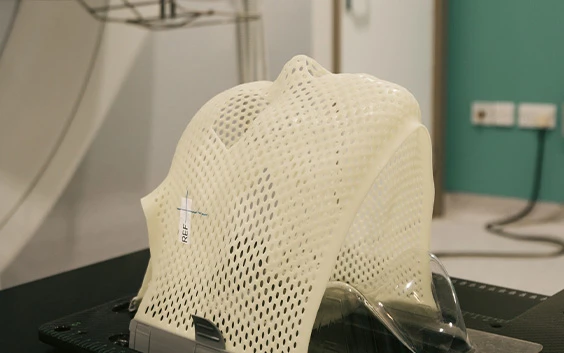

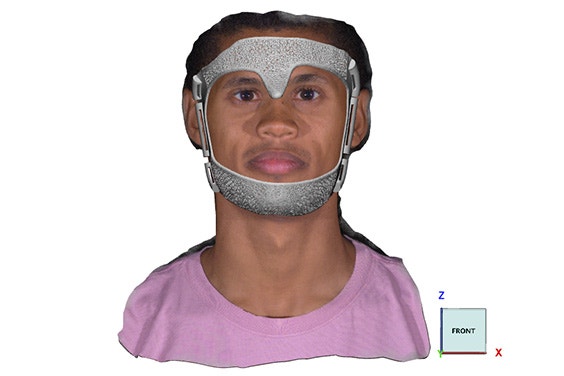

Standard of care immobilization device to precisely position the patient for treatment (left) and the 3D printed alternative (right). Left photo credit: National Cancer Institute

Production of complex radiotherapy devices

Complex radiotherapy devices can be created with 3D printing, like boluses or compensators, which can be difficult or impossible to create using traditional manufacturing methods. This technology allows for precise control over the shape and thickness of these devices, which can improve treatment accuracy and reduce the need for repositioning during treatment.

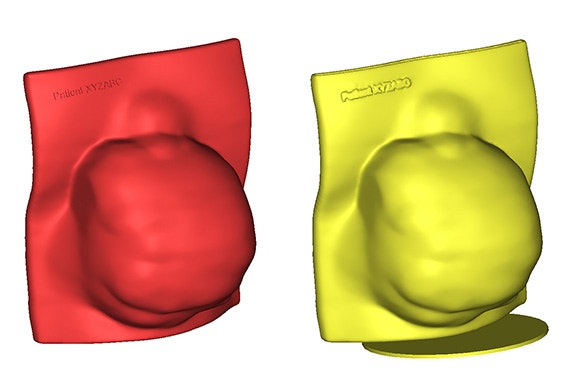

Standard of care bolus radiotherapy device (left) and 3D-printed alternative (right).

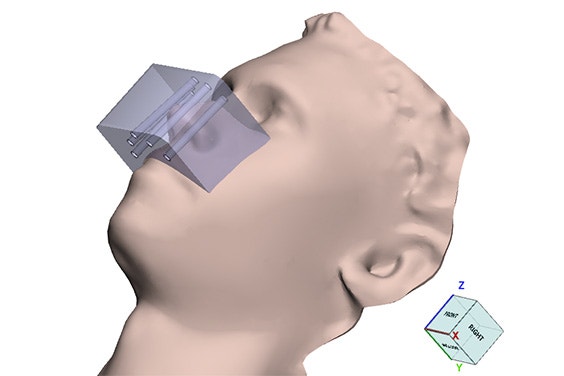

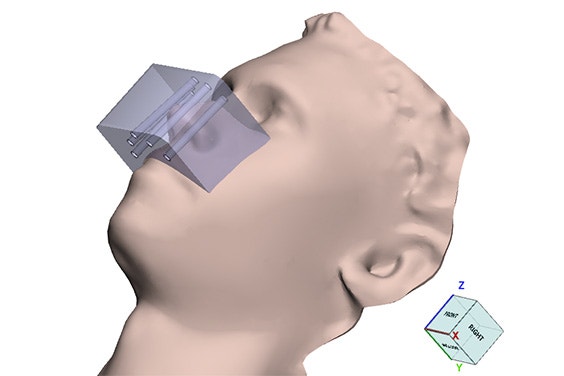

Personalization of brachytherapy applicators

Patient-specific brachytherapy applicators can be produced by 3D printing, which improves treatment accuracy and reduces the risk of side effects. Additionally, 3D printing allows for complex geometries for improved brachytherapy applicator design and functionality.

Creation of patient-specific phantoms

3D printing can be used to create patient-specific phantoms for quality assurance and dosimetry studies. These phantoms can replicate the patient's anatomy, test treatment plans, and verify dose calculations.

Challenges of 3D printing for radiotherapy

Designing and printing patient-specific devices comes with unique challenges. Hospitals with established 3D labs, however, would be well-positioned to help radiotherapy departments address these difficulties. The main challenges associated with 3D printing in radiotherapy are summarized in the following five points:

1. Quality control

3D printing can produce complex and highly customized devices tailored to a patient's individual anatomy, but ensuring the devices’ quality and accuracy is paramount. 3D printing inaccuracies or errors can have serious consequences for patient treatment outcomes.

2. Material selection

Selecting appropriate materials for 3D printing in radiotherapy is critical. Material selection is an important consideration because printed devices also need to be radiation-resistant and maintain their structural integrity over the course of treatment; radiotherapy requires materials that are highly precise, durable, and biocompatible, which can limit the options for 3D printing. Air bubbles can also be problematic, as they can cause voids or inconsistencies in the printed devices which affects the accuracy and effectiveness of patient treatment. Techniques such as vacuum degassing, pressure application, and specialized equipment can be used to prevent air bubbles, and quality control procedures can detect and address their presence in printed devices.

3. Regulatory challenges

The use of 3D printing in radiotherapy is subject to regulatory requirements, including compliance with relevant standards for medical devices and radiation protection. This can add complexity and cost to the development and use of 3D-printed devices in radiotherapy.

4. Cost

While 3D printing can be highly effective for producing customized and complex devices, the cost of 3D printing can be significant. This can make it challenging for smaller clinics or hospitals to adopt this technology, and limits access to the benefits. A potential solution could be to print personalized molds in a cheaper material for the actual device.

5. Integration with clinical workflows

Integrating 3D printing into existing clinical workflows requires a collaborative skillset. Radiologists, physicists, and radiation therapists must work together to develop standardized processes for 3D printing and device production.

The potential of automation

By automating the design process, you can produce printed devices that meet specific quality standards that are accurate and precise. Automation can reduce the risk of printed device inaccuracies or errors, which can have serious consequences for patient treatment outcomes. An automated design process also addresses cost considerations associated with 3D printing in radiotherapy because it is possible to create more efficient and cost-effective personalized devices than with traditional manufacturing methods.

Additionally, automated design and scripting also help streamline integrating 3D printing into existing clinical workflows. By standardizing the design and production process, it's possible to ensure that the printed devices meet the necessary regulatory requirements, including compliance with relevant standards for medical devices and radiation protection.

L-103472-01

Credit header photo: Jo McNamara / Pexels

Teilen auf:

Das könnte Sie auch interessieren

Verpassen Sie nie wieder eine Story wie diese. Sie erhalten sie einmal im Monat in Ihren Posteingang.