Das erwartet Sie in dieser Schulung

Looking to use metal 3D printing in your business? This interactive session will prepare you to get started with metal 3D printing in your projects.

Join one of our experts as they guide you through the basics of metal 3D printing and when manufacturing parts with this technology makes technical and business sense. They'll determine which topics are most suitable for your needs and adjust the length of the course accordingly.

Praktische Informationen

Zielgruppe

Professionals interested in metal 3D printing

Niveau

Basic

Format

- Online

- In-person

Dauer

2 or more days

Kosten

Available upon request

What you will learn

- An overview of the metal 3D printing technologies and how they work

- Design considerations and methodology for metal 3D printing

- The basic principles of 3D printing and how to apply them to your business

Training from an industry leader

30+ years of AM expertise

Materialise is a pioneer in developing software and processes to enable successful 3D printing stories and businesses.

Taught by design engineers

Learn from AM experts who help big players across aerospace, medtech, automotive, and eyewear.

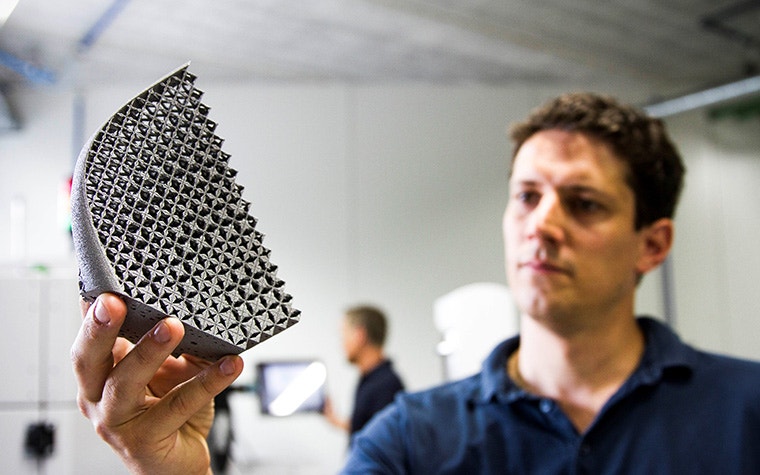

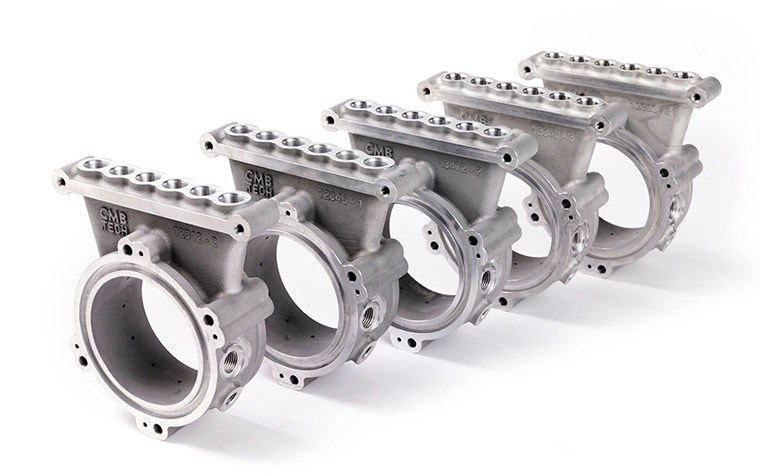

See real examples of industrial 3D printing

Find out how 3D printing factories worldwide deliver 3D prints — from prototypes to series manufacturing — with over two million parts printed annually.

Lessons included in this training

Frequently asked questions

Continue learning

What's next in your AM journey? Check out our other courses to continue advancing your skills.

An ideal introduction to industrial 3D printing. An AM expert will guide you through the basics of the most popular technologies, plus when and where it makes sense to print your parts.

Discover various methodologies and workflows for metal 3D printing, plus gain insight into the cost savings, integrated functionality, and increased performance associated with design for additive manufacturing (DfAM).

Discover various methodologies and workflows for working with polymers, plus gain insight into the cost savings, integrated functionality, and increased performance associated with design for additive manufacturing (DfAM).