CASE STUDY

Smart Design, Smart Mobility: KLIO Contributes to South Korea’s Smart Mobility

Driving pleasure, ergonomics and safety have always been important for the automotive industry. A rising new trend is smart mobility. This means applying innovation and modern technology to stimulate sustainable mobility. One of the goals of smart mobility is to cope with the negative effects of mobility such as traffic jams, pollution and traffic casualties.

Under the theme of ‘Smart Design, Smart Mobility’, the Seoul Smart Mobility International Conference and Exhibition was the venue where experts and Seoul citizens could discuss and experience the present and the future of South Korea’s smart mobility. KLIO Design participated in the exhibition and presented their Open Mobility Structure Concept, powered by 3D-printed car parts.

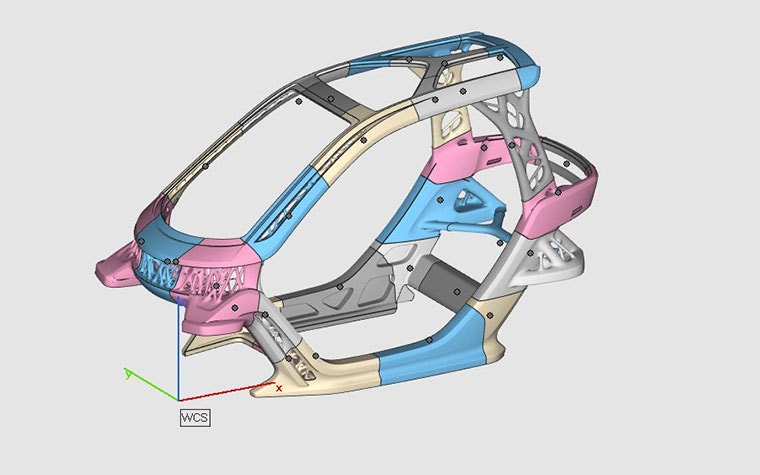

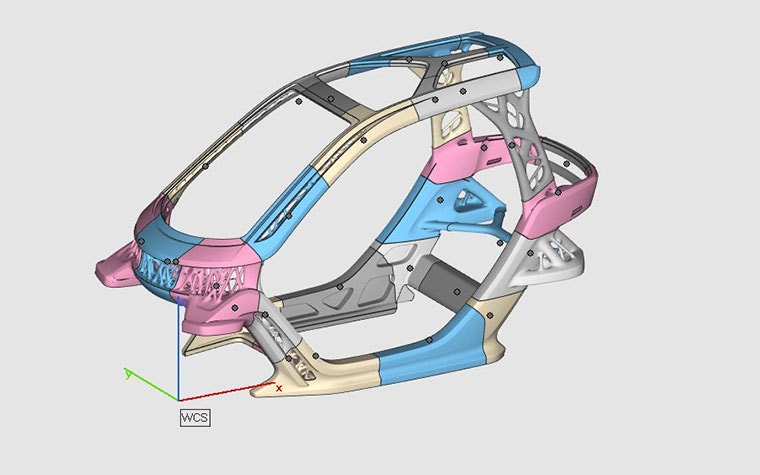

The Open Structure Mobility Concept

KLIO Design’s Open Structure Mobility Concept allows the user to combine different car body designs on a small standardized platform according to the number of passengers, the purpose of use and the environment. This open concept encourages mutual cooperation, instead of supplier-oriented business.

The platform design is made up of optimized structures to reduce the weight of the car and at the same time ensure stability despite its small size. To avoid mold creation and allow for mass customization, the wheel cover, wheel guard, steering wheel and parts of the space frame were 3D printed.

Optimizing the Design of the Car Frame

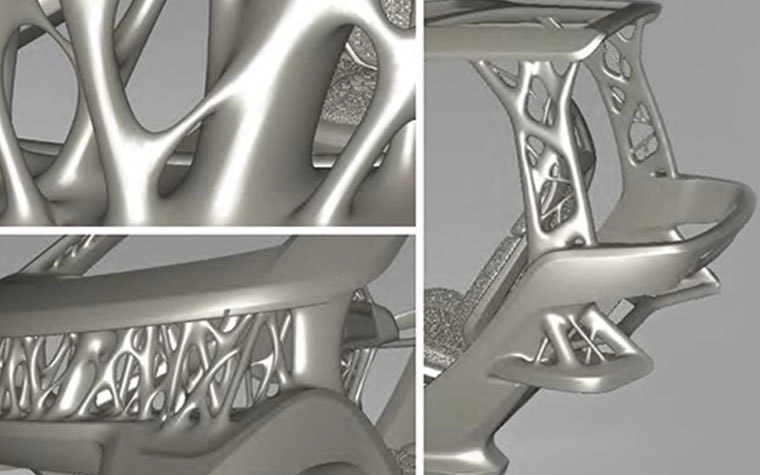

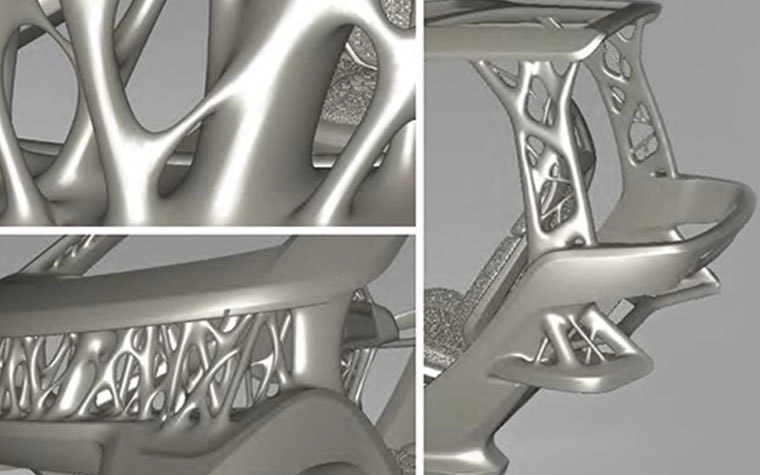

After designing the car frame using NURBS surfaces, it was topologically optimized, taking material property into account. Since the topologically optimized design couldn’t be 3D printed right away, Materialise 3-matic software was used to smoothen and redesign it on an STL level, making it 3D printable and reinforcing the strength of the structure. KLIO Design also used Materialise 3-matic to apply lightweight structures in the pillars. Since the frame needed to be connected to an underbody, every time the mounting points of the underbody changed, the frame required editing.

“Until the mounting points were set, there was iterative work of deleting structures and filling holes. Thanks to Materialise 3-matic, we could edit directly on an STL level and save time.”

— Jeongche Yoon, General Manager at KLIO Design

KLIO Design used 3-matic’s editing features when preparing their file for 3D printing. They cut the 3D model into pieces fitting the bed size of a printer and re-adjusted its thickness.

“Materialise 3-matic is a great software, whereas exporting high-quality designs with other software is not always possible. Compatibility with design data is also a great benefit.”

They then designed assembly parts in Alias software and with Materialise 3-matic, they divided the parts, hollowed them and created a hole to get rid of powder from the inside.

“One of the strengths of Materialise software is the ability to realize complex, organic structures and patterns that are difficult or even impossible to create with existing manufacturing methods, as well as the ability to visualize and edit huge data,” adds Yoon.

Optimizing the design of the car seat

Although the final shape of the car seat was more complicated than the one of the car frame, the work process was rather simple. KLIO Design divided the car seat according to its cushioning areas. Assuming that it would be difficult to assemble the printed parts, they decided to not cut the cushioning areas, but print them in one part.

They imported the car seat, designed with NURBS surfaces, to Materialise 3-matic and applied lightweight structures. Then they scaled and readjusted the beam thickness.

“Materialise 3-matic is intuitive when applying lattices and simple to create data for 3D printing. The best benefit for us is its format – you can work on your 3D data in a format lighter than STL when applying complex and complicated 3D lattices, which enabled us to work with a regular computer. This format didn’t require conversion to STL and the part could be printed directly on an EOS printer via the EOS Build Processor. Needless to say, we could convert to STL stably, which allowed us to work on the design conveniently.”

Watch this video to experience how KLIO Design worked on the open mobility concept. Jump to 1:45 for the printed parts!

All images: courtesy of KLIO Design

Share on:

This case study in a few words

Automotive industry

Materialise 3-matic

Materialise Magics

Materialise Build Processor

Create a light but safe car

Avoiding mold creation

Allowing mass customization

How we helped

Generate lattices, create textures for an aesthetic finish, and achieve post-topology optimization.

Optimize and automate support generation with options tailored to different materials, technologies, and geometries.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.