CASE STUDY

Sagrada Familia: Magics Meets Modernism

The world-famous Sagrada Familia cathedral in Barcelona has been using 3D printing since 2001 to continue the work of the great designer Antoni Gaudí. This modernist architect was not able to finish the work during his life. With the assistance of Materialise Magics software, Gaudí’s glorious magnum opus is well on its way to completion.

Hand-crafted spires, pointed arches and columns

Gaudí himself realized the importance of moving from a 2D plane to a 3D one. He found that 2D models were not the best way to design the cathedral and instead turned to making 3D models of his ideas. Unfortunately, many of the blueprints were destroyed during the Spanish Civil War and the remaining ones are often incomplete. Consequently, the Sagrada Familia consortium has been creating various prototypes to visualize the complex designs and figure out how a new part can fit in the broader picture. Before they had encountered Additive Manufacturing (AM), they handcrafted the models. Because of the complex nature of Gaudí’s design, this was a time-consuming and expensive process.

The right software for big architectural challenges

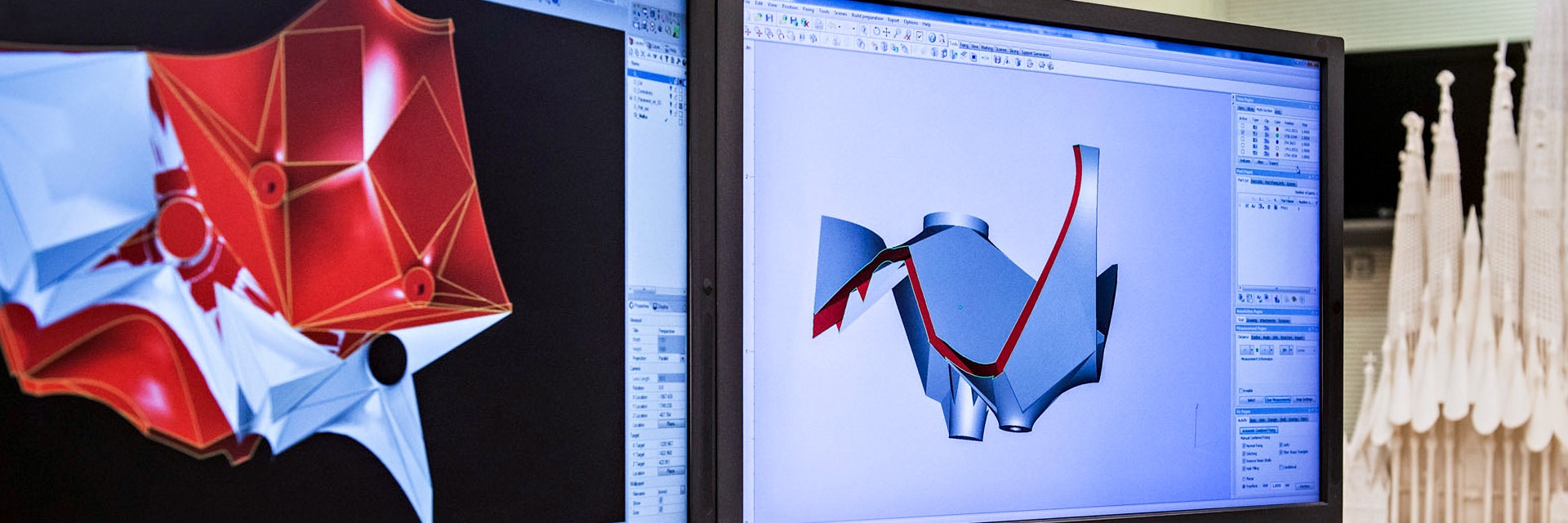

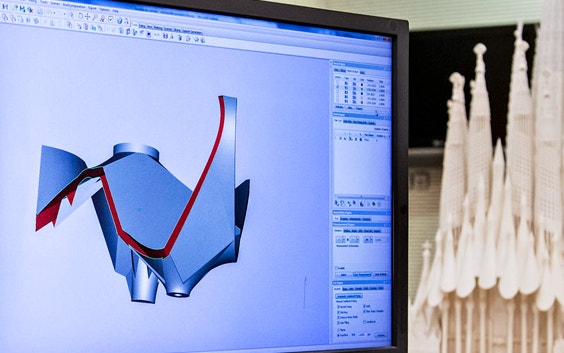

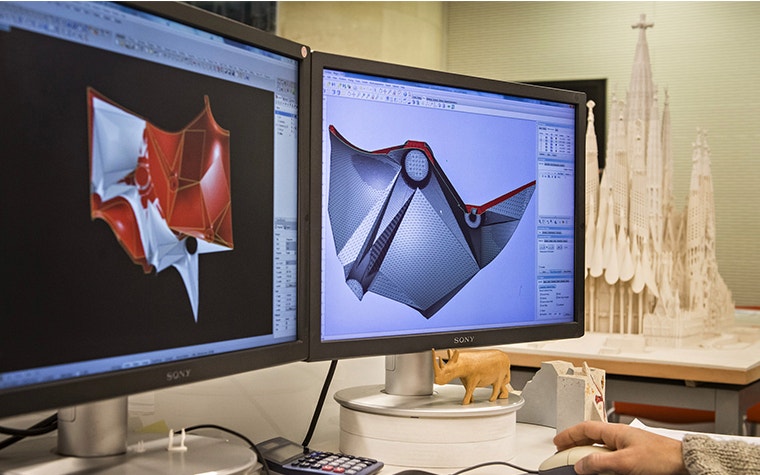

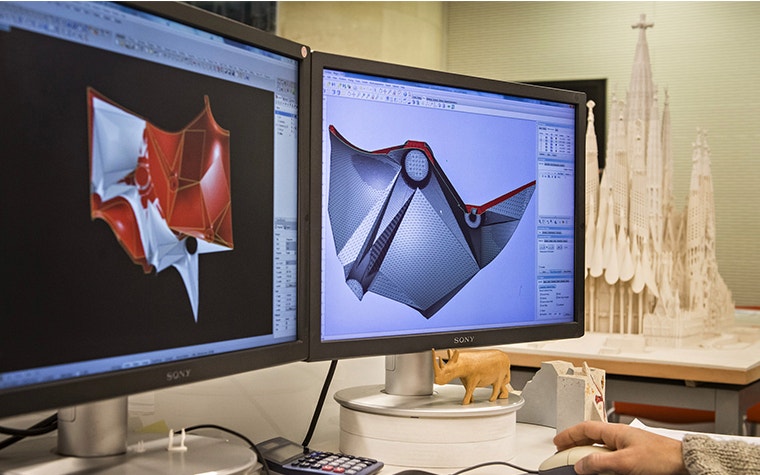

With the rise of AM technology, working with 2D designs to construct the Sagrada Familia no longer makes sense. 3D printing is the ideal method to represent the whimsical, spiky forms and twisted towers in the perfection they deserve. Because of their large sizes and complexity, architectural files are often difficult to handle. Materialise Magics has been helping the architects make cumbersome STL files ready for production in a matter of minutes. Problem areas are visualized and parts can be analyzed and repaired in detail, so that future quality issues can be avoided.

To prepare the data for printing, the consortium requires an advanced software package with specific file fixing and cutting tools and Materialise Magics is well-suited for big architectural challenges like this. Materialise’s software has been supporting the construction of the Sagrada Familia for over thirteen years now!

The file fixing normally happens using the Fix Wizard or the ShrinkWrap features. Both are automatic tools, which can be used in combination or separately, within an efficient workflow. ShrinkWrap in particular allows users to transform impossible architectural designs into printable ones. Thanks to its complex algorithm, a thin layer is wrapped around the original model and shrinks afterwards, while maintaining details intact. In this way all the errors are fixed, resulting in watertight, manageable data.

Since the design is sometimes too large to be printed in one piece, cutting it into multiple parts is often the only possible solution. To make sure that the parts can be reassembled in the right direction, the Cut & Punch function cuts sections with integrated connector pins and perforations for a perfect fit.

The digital prototypes are brought to life using ColorJet printing. This is a popular printing technique for architectural models thanks to its full use of colors.

Swiftly moving toward the last stones

Making prototypes in 3D allows architects to work in a more detailed way and at a scale the human hand cannot produce. Materialise Magics helps the architects create various complex prototypes, thus guiding decisions about the cathedral’s design while staying true to Gaudi’s style. Using Materialise Magics has helped keep the Sagrada Familia vision together, and with its aid, the cathedral is anticipated to be complete in 2026.

Share on:

This case study in a few words

Architecture

Materialise Magics

Advanced data preparation software

Rapid prototyping

Prepare complex architectural files for 3D Printing

Cutting, file fixing, ShrinkWrap for most challenging errors