Automotive

Going from concept to car, together

Build it fast; build it well; build it affordably — the mantra of the automotive industry. From quick, performant prototypes and visual models to small series manufacturing and automotive tooling, you can tick every box by bringing in 3D printing. Discover how Materialise can help you do it with a portfolio of services dedicated to every stage of the automotive industry workflow.

Why choose 3D printing?

Rapid time-to-market

Additive manufacturing empowers iterative design. Create, test, and validate designs to get your product to market faster than ever before, or speed up quality management through 3D-printed laser inspection fixtures.

Manage costs and risk

Shorten your supply chain and reduce your storage burden with just-in-time production, and produce small series without the need for cumbersome manufacturing tools. Reduce health-and-safety risks and cut production time with lightweight 3D-printed handheld jigs.

Embrace innovation

Create customized products, explore and test new ideas, and produce small series of high-end parts quickly and cost-effectively through the benefits of additive manufacturing.

Why choose Materialise Manufacturing?

On-hand expertise

When projects get complicated, remove the stress with the support of an expert team. We’ll help manage those complex printing requirements, multiple technologies, assembly needs, and beyond.

Diverse services

Access a complete portfolio of services dedicated to the needs of the automotive industry, from product development and manufacturing to assembly and quality control.

Barrierless prototyping

Create and test new parts quickly and easily without compromising on quality. Order online and choose from an extensive range of finishes and materials, from engineering-grade to aesthetic.

Think big

Size is no issue here. Print models up to 2.1 m in a single piece with our proprietary Mammoth Stereolithography technology.

Design and engineering expertise

Our Design & Engineering team will help you go from concept to creation and even optimize your design for 3D printing along the way.

Ideal materials for the automotive industry

PerFORM

Technology

Stereolithography

Description

A resin with ceramic particles, PerFORM offers high stiffness and strength, as well as excellent heat resistance and detail. It is ideal for prototyping and for rapid tooling for injection molds.

Key characteristics

- Stiffness comparable to glass fiber-reinforced polycarbonate

- High thermal resistance and excellent detail resolution

- Superior sidewall quality

- Max part dimensions: 800 x 800 x 585 mm

ProtoGen White

Technology

Stereolithography

Description

ProtoGen White's resilience, surface quality, and thermal properties make it suitable for general-purpose applications such as RTV molding patterns, highly detailed parts, and durable concept models.

Key characteristics

- Similar properties to ABS

- Resilient material with good surface quality

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

Taurus

Technology

Stereolithography

Description

Taurus has the look and feel of an injection-molded part, offering strong mechanical properties and high surface detail. It's an ideal choice for form-, fit-, and function-testing, as well as functional prototypes.

Key characteristics

- Injection-molded look and feel

- Strong mechanical properties

- High surface detailing

- Max part dimensions: 480 x 480 x 560 mm

Poly1500

Technology

Stereolithography

Description

Poly1500 is a durable, resilient material that offers high surface quality and dimensional accuracy. With properties similar to polypropylene, it is ideal for functional prototypes.

Key characteristics

- Similar properties to polypropylene

- Good durability, impact resistance, and heat resistance

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

TuskXC2700T

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700T is a strong material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes and high-end finished models. Transparent finishes possible.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Great surface quality, with transparent finishes possible

- Among the largest printing volumes of stereolithography materials

- Fast Lane service available for online orders of TuskXC2700T – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 2,000 x 700 x 788 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

Titanium (Ti₆Al₄V)

Technology

Metal 3D printing

Description

Ti₆Al₄V is a lightweight titanium alloy with excellent mechanical strength and superior corrosion resistance, making it ideal for functional prototypes and high-performance end-use parts.

Key characteristics

- Excellent mechanical properties

- Lightweight, with a high strength-to-weight ratio

- High corrosion and temperature resistance

- Suitable for post-machining

- Max part dimensions: 250 x 250 x 305 mm

Inconel (IN718)

Technology

Metal 3D printing

Description

Inconel (IN718) is a high-strength, corrosion-resistant alloy with exceptional thermal resistance. Ideal for functional prototypes and high-performance parts that need to withstand extreme conditions.

Key characteristics

- Exceptional thermal resistance up to 700°C

- High corrosion resistance

- High yield, tensile, and creep-rupture strength

- Suitable for post-machining

- Max part dimensions: 250 x 250 x 305 mm

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

ABS

Technology

Fused deposition modeling

Description

Known for its toughness, durability, and affordability, ABS is one of the most widely used industrial thermoplastics. It is suitable for prototyping, tooling, and end-use parts.

Key characteristics

- Tough, durable material

- High impact strength

- Up to 80% of the strength of injection-molded ABS

- Fast Lane service available for online orders of ABS White/Black – Normal finish

- Max part dimensions: 300 x 300 x 300 mm

- Max part dimensions (Fast Lane orders): 250 x 250 x 300 mm

Polycarbonate

Technology

Fused deposition modeling

Description

Polycarbonate is a Blue Card-certified flame-retardant thermoplastic with excellent impact strength, dimensional stability, and thermal resistance. It is ideal for prototypes, tooling, and end-use parts.

Key characteristics

- Excellent impact strength and temperature resistance

- Flame retardant — Blue Card-certified, UL 94 HB certified

- High flexural and tensile strength, and very high dimensional accuracy

- Max part dimensions: 914 x 610 x 914 mm

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

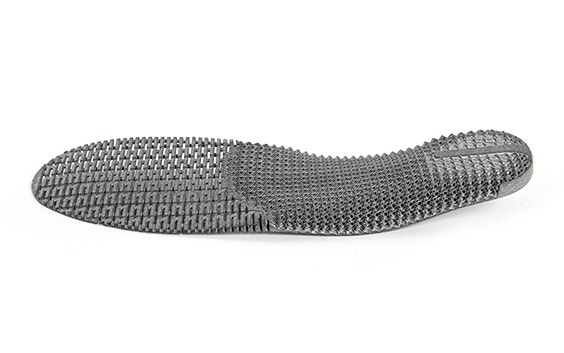

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

Typical 3D printing applications in automotive

Concept models

Design true-to-life models, big or small, and do it faster than ever before, thanks to additive manufacturing and the help of an expert team. Choose from a wide range of visual materials and finishes, such as texturing and painting, to create your concepts.

Jigs and fixtures

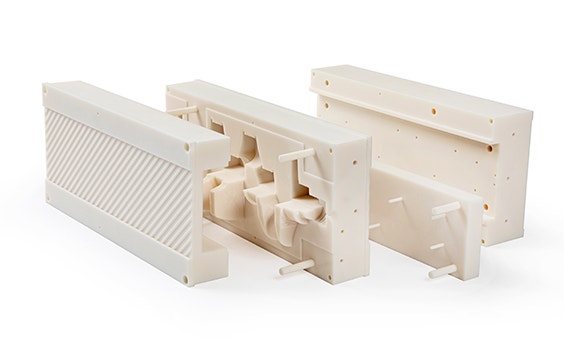

Bridge the gap between prototyping and manufacturing with RapidFit’s clever jigs and fixtures. Ensure optimal quality and ease of assembly with custom solutions for every department, from quality control to the production floor.

Wind tunnel testing

Put your designs to the test in realistic and challenging environments. Take advantage of our design and production expertise to analyze part performance and ensure your concept meets the strictest requirements.

Fit, form, and function prototypes

Create accurate and functional prototypes faster than ever before with cost-effective online ordering that keeps you in full control. Choose from a wide range of engineering-grade materials, including polymers and metals, to accurately mimic the characteristics of your final part.

After-market and spare parts

Create after-market or spare parts on demand through 3D printing and vacuum casting. Ensure they meet every industry standard and the strictest regulations with access to production-grade materials and stringent quality control. Our scanning and redesign expertise can help you avoid storage costs and the risk of obsolescence.

Our products and services for the automotive industry

Ready to start your project with us? Discover our solutions, ideal for your industry.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Work with our experts to translate your business challenges into 3D printing opportunities and identify the applications that can help you meet your needs.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Go all in with ACTech. As specialists in rapid prototyping, all casting and CNC machining processes are carried out in-house, ensuring you get the highest quality product in record time, finished and ready to install.

Through expert knowledge of engineering, 3D printing, and software development, the RapidFit team provides jigs, fixtures, and tools for the automotive industry that save costs, time, weight, and space.

Inspiration

Get inspired for your next project with a look at how 3D printing has made its mark in the automotive industry.

Other industries we work in

Navigate the future of aerospace with shorter lead times, more affordable small series production, and the unrivaled design freedom that additive manufacturing can offer.

Create truly unique solutions, enable mass customization across your product line, move from design to serial production quickly and affordably, and benefit from de-risked and sustainable supply chains.

Enter a new era of more sustainable, on-demand manufacturing where creativity and innovation have no boundaries and where quick time-to-market, and zero stock-risk, boost business agility.