Materialise Mindware

How We Help

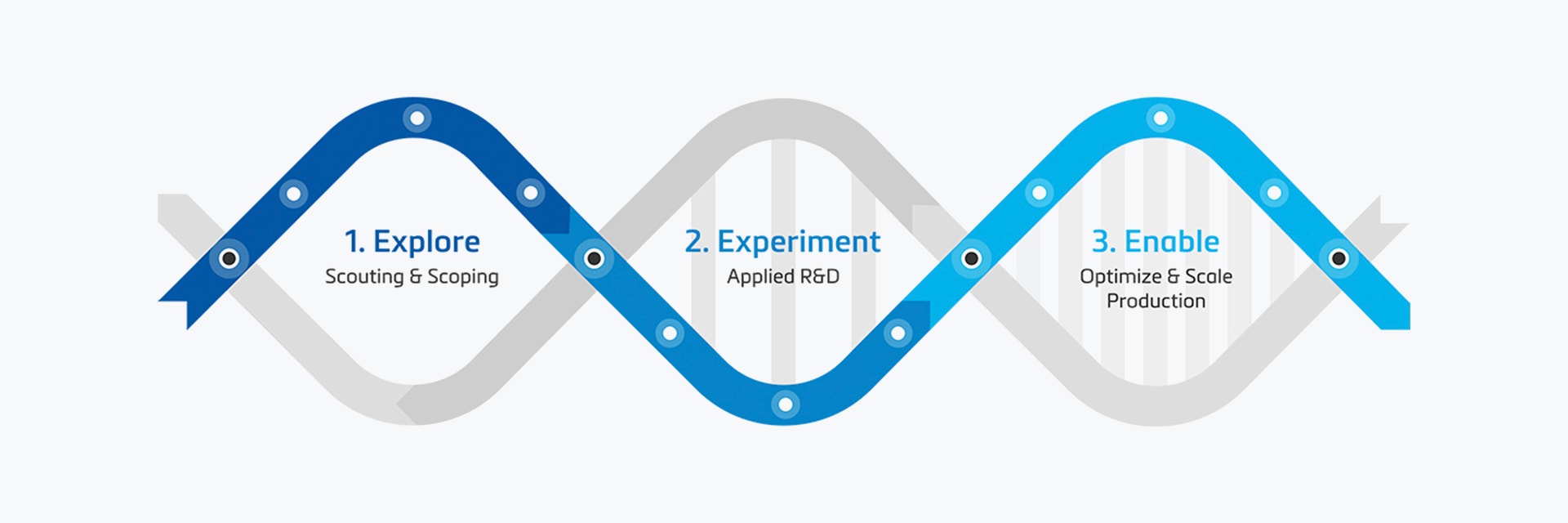

With Mindware additive manufacturing (AM) consulting, our goal is to help you make the most of AM on your terms. Whether you’re in the early stages of exploring AM, already experimenting with bringing AM to life in your organization, or ready to optimize and scale your AM production, we’ll work together to build a module-based program tailored to your specific needs and goals. Read more about the modules below and get in touch so we can craft the right program for you.

Explore: kickstarting additive adoption

You’re convinced of the value of AM, but perhaps others in your business still need persuading. Or maybe your team is fully on board and needs help finding optimal applications. Through our Explore solutions, we help you translate your business challenges into tangible AM opportunities. And to set you on the best path to realizing those opportunities, we guide you through the key considerations for defining a robust strategy and building the necessary roadmaps.

AM foundation sessions

Disjointed knowledge about AM makes it impossible to make informed decisions and plot a path to AM success. This module, delivered in the form of interactive online or onsite sessions, helps you and your team understand the possibilities and limitations of AM across materials and technologies. It provides a solid base on which to explore how 3D printing can deliver the results and growth you need.

AM strategy and roadmap development

Without a clear AM strategy, uncoordinated efforts can result in wasted time, sub-optimal results, and missed opportunities. This module, consisting of various strategy workshops between Mindware business and technical consultants and your core team, is all about identifying priorities and objectives for your business. It establishes which product categories and product lines to focus on and takes a pragmatic look at the different steps, time, and investments needed to reach your goals.

AM applications scan and assessment

The key to AM success is identifying the applications that can bring the biggest business impact and where 3D printing is actually feasible. In this module, we assist you in identifying the best AM applications within your selected focus areas using methods such as database analysis, stakeholder interviews, and production line scanning. We then perform a deeper part assessment to determine feasibility, drawing on business input, product requirements, 3D part data, and 3D printing know-how.

Experiment: application research and development

You’re committed to incorporating AM into your business model, and your strategy is in place. Everyone is clear on why AM is the chosen route and which applications you will tackle. Now it’s time to figure out how to make it happen. Our Experiment solutions are all about collaborative, hands-on research and development to bring your applications to life. We help you find the right solutions to validate your business case and ensure your investment is a success.

Material and technology feasibility studies

Additive manufacturing encompasses a wide range of technologies and an ever-growing choice of materials and post-processing techniques — choosing the optimal combination for your application is key. In this module, we help you navigate the maze of options while keeping the focus on your critical product requirements. From clarification sessions to market research and concrete validation exercises, the result is conclusive recommendations on which paths to pursue.

Design and engineering for AM

Design is one of the critical success factors for a viable 3D-printed product. Understanding how to design or redesign a part to unlock the full potential of AM and your chosen technology and material is therefore hugely important. In this module, our AM design specialists can work hand-in-hand with you to create entirely new product visions or help you adapt existing designs to improve costs, printability, and functionality.

Rapid prototyping and POC validation

There’s nothing like having a physical part in your hands to fully understand the value 3D printing can bring to your product development. Whether for a benchmark study or for creating functional prototypes of your new product, our team can quickly validate theoretical assumptions by building components using our extensive range of in-house technologies. Our software engineers can also help you develop mock-ups for your digital customer journeys and back-end workflows.

Enable: scaling AM adoption

You’re no stranger to additive manufacturing, and you’ve seen first-hand the benefits 3D printing can bring to your business. Our Enable solutions help you take AM to the next level through serial manufacturing. With a focus on fine-tuning your production line to ensure the repeatability and reliability you need, we support you in scaling your AM operations to make efficiency gains and unlock further business growth.

AM process optimization

To successfully scale from prototype or low volumes to serial manufacturing, you need to precision-engineer your process to optimize costs while keeping quality consistently high. Based on a tailored analysis of your AM component, our multidisciplinary experts fine-tune every parameter that influences the build cost and quality. Even down to the intricacies of optimizing the machine's standard scanning and hatching strategies, all to deliver the best possible part off the machine.

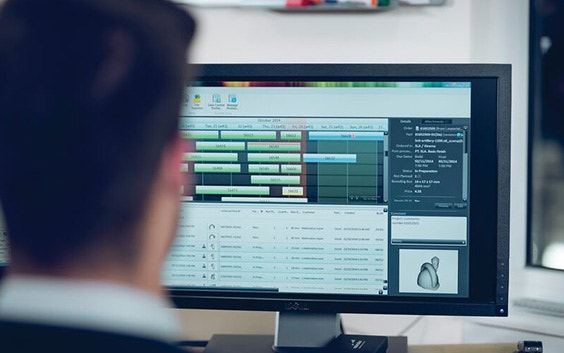

AM workflow automation

With additive manufacturing, mass customization becomes financially viable — provided you have processes in place to handle the large amounts of individual data, generate individualized designs fast, and manage the production flow and logistics. In this module, we support you in designing, testing, and implementing the optimal digital end-to-end workflow to reduce manual effort on repetitive tasks and ensure the most consistent output.

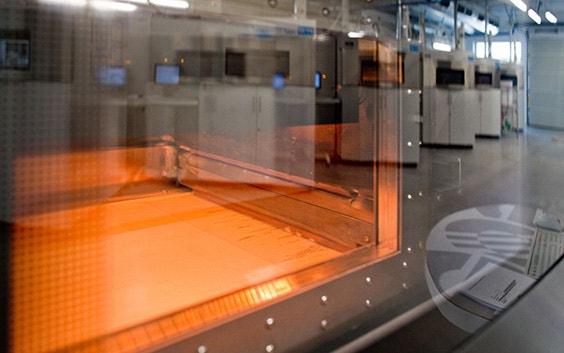

Building an AM production line

Scaling up AM production means replicating quality standards while bringing part costs within tight budgets. In this module, we start from the specific challenges of your business or existing production line and set up a tailored program together with you. Drawing on our own experience in building scaled production lines for industries like aerospace, medical, and eyewear, we cover everything from a machine and material roadmap to recruitment profile advice for the optimal infrastructure and team.

AM masterclasses

Whatever stage you’re at in your AM adoption, we can create tailored masterclasses to complement your Mindware program. From broad technology and material introductions or industry-specific workshops to design for AM training courses, we’ll determine together how to bridge the gap between your team’s current skills and where you want to go.

Design and engineering for AM

As an integral part of AM adoption success, design and engineering for AM is a key pillar of our Mindware consultancy. From advice and training to on-premise support, Mindware lets you tap into specialist know-how and trusted support to accelerate your AM implementation.

Product development

If you want to unlock the benefits additive manufacturing offers for your project, it makes sense to design towards them from the outset. Fully understanding the interplay between your application, production technologies, and material requirements is crucial. By involving our design for additive manufacturing (DfAM) team in your ideation phase, you’ll get expert insight and advice that’s tailored to your specific needs to get your project off to the best possible start.

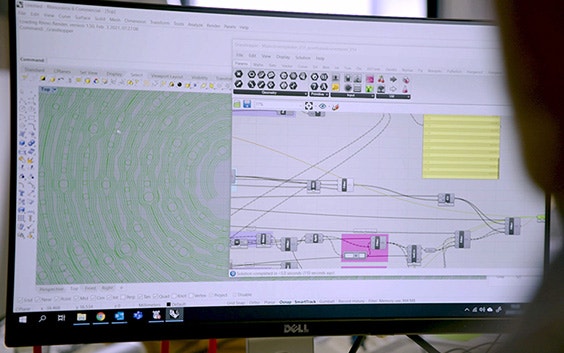

Design automation

Achieve efficient mass customization by tweaking designs within a predefined set of boundaries based on specific design parameters. We use algorithm-based techniques to produce 3D models from a set of rules, making it possible to easily adjust parameters and repeat rulesets to create any kind of model.

Opportunity spotting

Not sure where to start with introducing AM in your operations? Our design experts inspect your production line, in person or virtually, to identify bespoke applications that can help you raise operational efficiency or foster product innovation. We’re there to brainstorm the right solution in collaboration with your team and deliver an AM application with a solid business case.

DfAM training

Discover methodologies and workflows to understand and apply the design benefits of AM, save costs, integrate functionality, and enhance performance. We offer training courses customized to your team’s training needs and applications, conducted at your premises or ours.

On-premise expertise

For those times when you need to bolster your in-house expertise, we can place our DfAM specialists ‘inside’ your business to support you and join your engineering team. Ask for their hands-on advice in selecting the most appropriate technologies, materials, and finishes. Our design engineers can also work alongside you to get your files ready for 3D printing.

Inspiration

Discover more on how our Mindware consultants help businesses grow.